Q2-27.

Radomes, wing tips, stabilizer tips, and an-

NONMETALLIC MATERIALS

tenna covers are made from what type of

In addition to metals, various types of plastic mate-

plastic?

rials are found in aircraft construction. Transparent

plastic is found in canopies, windshields, and other

METALLIC MATERIALS

transparent enclosures. Handle transparent plastic

LEARNING OBJECTIVE: Identify the

surfaces with care, because this material is relatively

soft and scratches easily. At approximately 225F,

properties of metallic materials used in aircraft

construction.

transparent plastic becomes soft and very pliable.

Metallurgists have been working for many years to

Reinforced plastic is made for use in the

improve metals for aircraft construction. Each metal

construction of radomes, wing tips, stabilizer tips,

has certain properties and characteristics that make it

antenna covers, and flight controls. Reinforced plastic

desirable for a particular application, but it may have

has a high strength-to-weight ratio and is resistant to

other qualities that are undesirable. For example, some

mildew and rot. Its ease of fabrication makes it equally

metals are hard, others comparatively soft; some are

suitable for other parts of the aircraft.

brittle, some tough; some can be formed and shaped

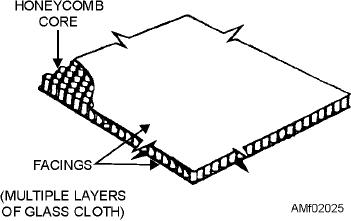

Reinforced plastic is a sandwich-type material. See

without fracture; and some are so heavy that weight

figure 2-25. It is made up of two outer facings and a

alone makes them unsuitable for aircraft use. The

center layer. The facings are made up of several layers

metallurgist's objectives are to improve the desirable

of glass cloth, bonded together with a liquid resin. The

qualities and tone down or eliminate the undesirable

core material (center layer) consists of a honeycomb

ones. This is done by alloying (combining) metals and

structure made of glass cloth. Reinforced plastic is

by various heat-treating processes.

fabricated into a variety of cell sizes.

You do not have to be a metallurgist to be a good

AM, but you should possess a knowledge and

High-performance aircraft require an extra high

understanding of the uses, strengths, limitations, and

strength-to-weight ratio material. Fabrication of

other characteristics of aircraft structural metals. Such

composite materials satisfies the special requirement.

knowledge and understanding is vital to properly

This construction method uses several layers of

construct and maintain any equipment, especially

bonding materials (graphite epoxy or boron epoxy).

airframes. In aircraft maintenance and repair, even a

These materials are mechanically fastened to

slight deviation from design specifications or the

conventional substructures. Another type of composite

substitution of inferior materials may result in the loss

construction consists of thin graphite epoxy skins

of both lives and equipment. The use of unsuitable

bonded to an aluminum honeycomb core.

materials can readily erase the finest craftsmanship.

Q2-24.

What is the most widely used metal in modern

The selection of the specific material for a specific

aircraft construction?

repair job demands familiarity with the most common

Q2-25.

What is the world's lightest structural metal?

properties of various metals.

Q2-26.

At what temperature does transparent plastic

PROPERTIES OF METALS

become soft and pliable?

This section is devoted primarily to the terms used

in describing various properties and characteristics of

metals in general. Your primary concerns in aircraft

maintenance are such general properties of metals and

their alloys as hardness, brittleness, malleability, ductil-

ity, elasticity, toughness, density, fusibility, conductiv-

ity, and contraction and expansion. You must know the

definition of the terms included here because they form

the basis for further discussion of aircraft metals.

Hardness

Hardness refers to the ability of a metal to resist

abrasion, penetration, cutting action, or permanent

Figure 2-25.--Reinforced plastic.

2-21