the wing skin. In the extended position, the spoiler is

The pilot moves the trim tab by using cockpit

pivoted up and forward approximately 60 degrees

controls. The tab on the control surface moves in a

above the hinge point. The spoilers disturb the smooth

direction opposite that of the desired control surface

flow of air over the wing so that burbling takes place.

movement. The airflow striking the trim tab causes the

The lift is consequently reduced, and considerable drag

larger surface to move to a position that will correct the

is added to the wing.

unbalanced condition of the aircraft. For example, to

trim a nose-heavy condition, the pilot sets the elevator

Another type of spoiler in common use is a long,

trim tab in the "down" position. This causes the elevator

slender, curved and perforated baffle that is raised

to be moved and held in the "up" position, which, in

edgewise through the upper surface of the wing forward

turn, causes the tail of the aircraft to be lowered.

of the aileron. It also disrupts the flow of air over the

Without the use of the trim tab, the pilot would have to

airfoil and destroys lift. These spoilers are actuated

hold the elevator in the up position by exerting constant

through the same linkage that actuates the ailerons.

pressure on the control stick or wheel.

This arrangement makes movement of the spoiler

dependent upon movement of the aileron. The linkage

Construction of trim tabs is similar to that of the

to the aileron is devised so that the spoiler is extended

other control surfaces, although greater use is being

only when the aileron is raised. In other words, when

made of plastic materials to fill the tab completely.

the aileron moves downward, no deflection of the

Filling the tab improves stiffness. Tabs may also be

spoiler takes place.

honeycomb filled. Tabs are covered with either metal or

reinforced plastic. Trim tabs are actuated either

SPEED BRAKES.--Speed brakes are hinged,

electrically or manually.

movable control surfaces used for reducing the speed of

WING FLAPS.--Wing flaps are used to give the

aircraft. Some manufacturers refer to them as dive

aircraft extra lift. Their purpose is to reduce the landing

brakes or dive flaps. They are hinged to the sides or

speed, thereby shortening the length of the landing

bottom of the fuselage or to the wings. Regardless of

rollout. They are also used to assist in landing in small

their location, speed brakes serve the same purpose on

or obstructed areas by permitting the gliding angle to be

all aircraft. Their primary purpose is to keep aircraft

increased without greatly increasing the approach

from building up excessive speed during dives. They

speed. In addition, the use of flaps during takeoff serves

are also used in slowing down the speed of the aircraft

to reduce the length of the takeoff run.

prior to landing. Speed brakes are operated

hydraulically or electrically.

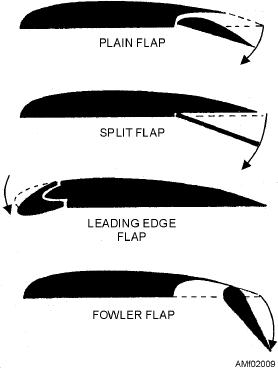

Most flaps are hinged to the lower trailing edges of

the wings inboard of the ailerons, however, leading

edge flaps are in use on some Navy aircraft. Four types

of flaps are shown in figure 2-9. The PLAIN flap forms

the trailing edge of the airfoil when the flap is in the up

position. In the SPLIT flap, the trailing edge of the

airfoil is split, and the bottom half is so hinged that it

can be lowered to form the flap. The FOWLER flap

operates on rollers and tracks. This causes the lower

surface of the wing to roll out and then extend

downward. The LEADING EDGE flap operates

similarly to the plain flap. It is hinged on the bottom

side and, when actuated, the leading edge of the wing

actually extends in a downward direction to increase

the camber of the wing. Leading edge flaps are used in

conjunction with other types of flaps.

SPOILERS.--Spoilers are used for decreasing

wing lift; however, their specific design, function, and

use vary with different aircraft.

The spoilers on some aircraft are long, narrow

surfaces hinged at their leading edge to the upper wing

skin. In the retracted position, the spoiler is flush with

Figure 2-9.--Types of flaps.

2-10