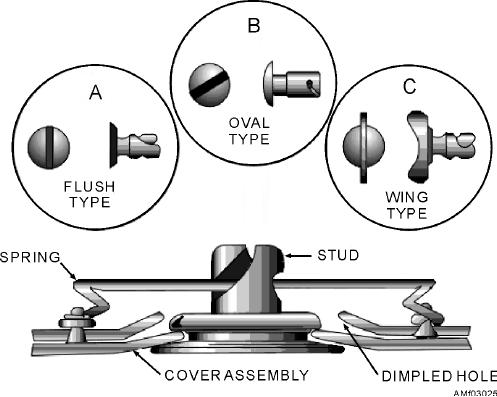

shown in views A, B, and C) and mounts in a dimpled

or cone-shaped washers--the latter being used with

hole in the cover assembly.

flush fasteners in dimpled holes. This fastener may be

distinguished from screws by the deep No. 2 Phillips

When the panel is being positioned on an aircraft,

recess in the stud head and by the bushing in which the

the spring riveted to the structural member enters the

stud is installed.

hollow center of the stud. Then, when the stud is turned

about one-fourth turn, the curved jaws of the stud slip

A threaded insert in the receptacle provides an

over the spring and compress it. The resulting tension

adjustable locking device. As the stud is inserted and

locks the stud in place and secures the panel.

turned counterclockwise one-half turn or more, it

screws out the insert to permit the stud key to engage

Miscellaneous Fasteners

the insert cam when turned clockwise. Rotating the stud

clockwise one-fourth turn engages the insert.

Some fasteners cannot be classified as rivets,

Continued rotation screws the insert in and tightens the

turnlocks, or threaded fasteners. Included in this

fastener. Turning the stud one-fourth turn

category are connectors, couplings, clamps, taper and

counterclockwise will release the stud, but will not

flat-head pins, snap rings, studs, and heli-coil inserts.

screw the insert out far enough to permit

re-engagement. The stud should be turned at least

FLEXIBLE CONNECTORS AND COU-

one-half turn counterclockwise to reset the insert.

PLINGS.--A variety of clamping devices are used in

connecting ducting sections to each other or to various

DZUS FASTNERS.--Dzus fasteners are available

components. Whenever lines, components, or ducting

in two types. A light-duty type is used on box covers,

are disconnected or removed for any reason, you should

access hole covers, and lightweight fairings. The

install suitable plugs, caps, or coverings on the

heavy-duty type is used on cowling and heavy fairings.

openings to prevent the entry of foreign materials. You

The main difference between the two Dzus fasteners is

should also tag the various parts to ensure correct

a grommet, which is only used on the heavy-duty

reinstallation. You should exercise care during

fasteners. Otherwise, their construction features are

handling and installation to ensure that flanges are not

about the same.

scratched, distorted, or deformed. Flange surfaces

Figure 3-25 shows the parts of a light-duty Dzus

should be free of dirt, grease, and corrosion. The

fastener. Notice that they include a spring and a stud.

protective flange caps should be left on the ends of the

The spring is made of cadmium-plated steel music

ducting until the installation progresses to the point

wire, and is usually riveted to an aircraft structural

where removal is necessary.

member. The stud comes in a number of designs (as

Figure 3-25.--Dzus fastener.

3-14