In most cases it is mandatory to discard and replace

seals and gaskets. You should ensure that seals and

gaskets are properly seated and that mating and align-

ment of flanges are fitted. This will prevent the exces-

sive torque required to close the joint, which imposes

structural loads on the clamping devices. Adjacent

support clamps and brackets should remain loose until

installation of the coupling has been completed.

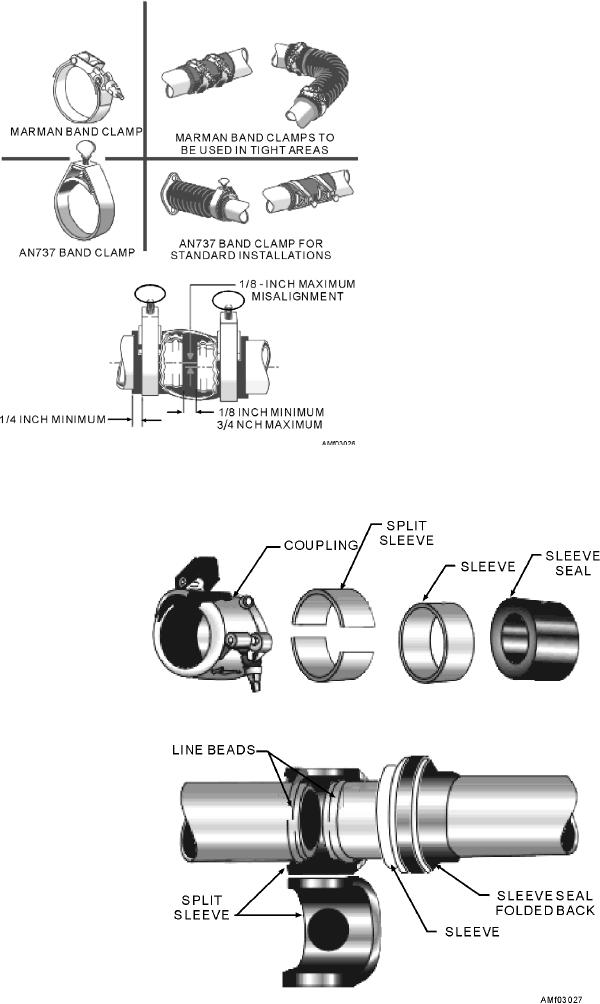

Some of the most commonly used plain-band

couplings are shown in figure 3-26. When you install a

hose between two duct sections, the gap between the

duct ends should be a minimum of 1/8 of an inch and a

maximum of 3/4 of an inch. When you install the

clamps on the connection, the clamp should be 1/4 of an

inch from the end of the connector. Misalignment

between the ducting ends should not exceed 1/8 of an

inch.

Marman clamps are commonly used in ducting

systems and should be tightened to the torque value

indicated on the coupling. Tighten all couplings in the

manner and to the torque value specified on the clamp

or in the applicable maintenance instruction manual.

When you install flexible couplings, such as the

one shown in figure 3-27, the following steps are

recommended to assure proper security:

Figure 3-26.--Flexible line connectors.

Figure 3-27.--Flexible line coupling.

3-15