nonself-locking nuts are used, they should be locked

NONSELF-LOCKING

with an auxiliary locking device such as a check nut or

NUTS.--Nonself-locking nuts require the use of a

lock washer. See figure 3-17.

separate locking device for security of installation.

There are several types of these locking devices

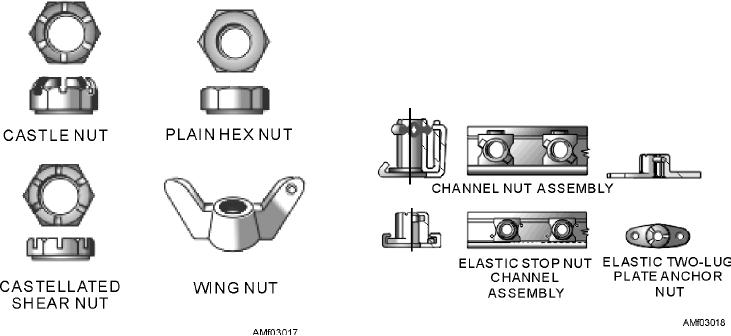

CASTLE NUTS.--These nuts are used with

mentioned in the following paragraphs in connection

drilled shank bolts, hex-head bolts, clevis bolts,

with the nuts on which they are used. Since no single

eyebolts, and drilled-head studs. These nuts are

locking device can be used with all types of

designed to be secured with cotter pins or safety wire.

nonself-locking nuts, you must select one suitable for

CASTELLATED NUTS.--Like the castle nuts,

the type of nut being used.

these nuts are castellated for safetying. They are not as

SELF-LOCKING NUTS.--Self-locking nuts

strong or cut as deep as the castle nuts.

provide tight connections that will not loosen under

CHECK NUTS.--These nuts are used in locking

vibrations. Self-locking nuts approved for use on

devices for nonself-locking plain hex nuts, setscrews,

aircraft meet critical strength, corrosion-resistance, and

and threaded rod ends.

temperature specifications. The two major types of

self-locking nuts are prevailing torque and free

PLATE NUTS.--These nuts are used for blind

spinning. The two general types of prevailing torque

mounting in inaccessible locations and for easier

nuts are the all-metal nuts and the nonmetallic insert

maintenance. They are available in a wide range of

nuts. New self-locking nuts must be used each time

sizes and shapes. One-lug, two-lug, and right-angle

components are installed in critical areas throughout

shapes are available to accommodate the specific

the entire aircraft, including all flight, engine, and fuel

physical requirements of nut locations. Floating nuts

control linkage and attachments. The flexloc nut is an

provide a controlled amount of nut movement to

example of the all-metal type. The elastic stop nut is an

compensate for subassembly misalignment. They can

example of the nonmetallic insert type. All-metal

be either self-locking or nonself-locking. See figure

self-locking nuts are constructed with the threads in the

3-18.

load-carrying portion of the nut out of phase with the

CHANNEL NUTS.--These nuts are used in

threads in the locking portion, or with a saw cut top

applications requiring anchored nuts equally spaced

portion with a pinched-in thread. The locking action of

around openings such as access and inspection doors

these types depends upon the resiliency of the metal

and removable leading edges. Straight or curved

when the locking section and load-carrying section are

channel nut strips offer a wide range of nut spacing and

forced into alignment when engaged by the bolt or

provide a multinut unit that has all the advantages of

screw threads.

floating nuts. They are usually self-locking.

PLAIN HEX NUTS.--These nuts are available in

BARREL NUTS.--These nuts are installed in

self-locking or nonself-locking styles. When the

drilled holes. The round portion of the nut fits in the

drilled hole and provides a self-wrenching effect. They

are usually self-locking.

INTERNAL-WRENCHING NUTS.--These

nuts are generally used where a nut with a high tensile

Figure 3-18.--Self-locking plate nuts.

Figure 3-17.--Nuts.

3-10