styles: protruding and countersunk. Pin retention is

accomplished by swaging the collar into the locking

grooves on the pin.

The blind lock bolt, shown in view B of figure 3-6,

is similar to the self-plugging rivet shown in figure 3-3.

It features a positive mechanical lock for pin retention.

Hi-Lok Fasteners

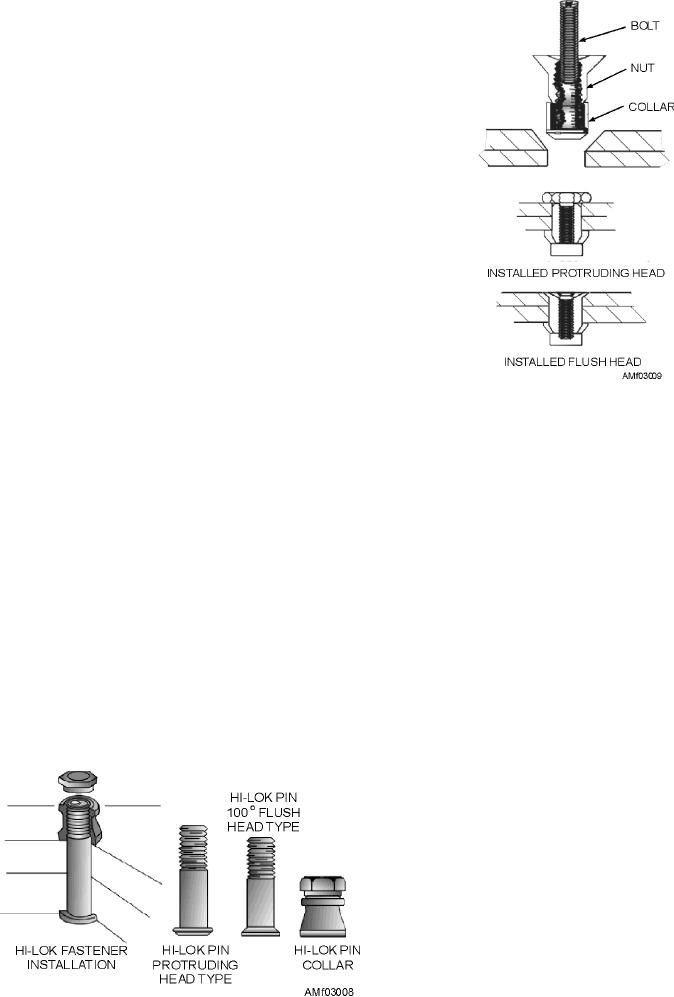

The hi-lok fastener, shown in figure 3-8, combines

the features of a rivet and a bolt and is used for

high-strength, interference-free fit of primary

structures. The hi-lok fastener consists of a threaded pin

and threaded locking collar. The pins are made of

cadmium-plated alloy steel with protruding or

100-degree flush heads. Collars for the pins are made of

anodized 2024-T6 aluminum or stainless steel. The

threaded end of the pin is recessed with a hexagon

socket to allow installation from one side. The major

diameter of the threaded part of the pin has been

truncated (cut undersize) to accommodate a 0.004-inch

Figure 3-9.--Jo-bolt.

maximum interference-free fit. One end of the collar is

internally recessed with a 1/16-inch, built-in variation

head styles available for Jo-bolts are the 100-degree

that automatically provides for variable material

flush head, the hexagon protruding head, and the

thickness without the use of washers and without

100-degree flush millable head.

fastener preload changes. The other end of the collar

has a torque-off wrenching device that controls a

FASTENERS (THREADED)

predetermined residual tension of preload (10%) in the

fastener.

Although thousands of rivets are used in aircraft

construction, many parts require frequent dismantling

Jo-Bolt Fasteners

or replacement. For these parts it is more practical to

use some form of threaded fastener. Furthermore, some

The Jo-bolt, shown in figure 3-9, is a high-strength,

joints require greater strength and rigidity than can be

blind structural fastener that is used on difficult riveting

provided by riveting. Manufacturers solve this problem

jobs when access to one side of the work is impossible.

by using various types of screws, bolts, nuts, washers,

The Jo-bolt consists of three factory-assembled parts:

and fasteners.

an aluminum alloy or alloy steel nut, a threaded alloy

Bolts and screws are similar in that both have a

steel bolt, and a corrosion-resistant steel sleeve. The

head at one end and a screw thread at the other, but there

are several differences between them. The threaded end

of a bolt is always relatively blunt, while that of a screw

may be either blunt or pointed. The threaded end of a

bolt must be screwed into a nut, but the threaded end of

the screw may fit into a nut or other female

arrangement, or directly into the material being

secured. A bolt has a fairly short threaded section and a

comparatively long grip length (the unthreaded part); a

screw may have a longer threaded section and no

clearly defined grip length. A bolt assembly is

generally tightened by turning its nuts. Its head may or

may not be designed to be turned. A screw is always

designed to be turned by its head. Another minor but

Figure 3-8.--Hi-lok fastener.

3-5