GRAPHITE.--Carbon graphite fibers were first

developed by Thomas Edison while experimenting

with the incandescent light bulb. It is made from

synthetic material and carbonized in an inert

environment at temperatures around 3000F. Carbon

fibers are readily woven into various patterns. They are

used to manufacture complex contoured parts. The

majority of advanced composite parts on naval aircraft

are made of carbon fibers.

KEVLAR.--DuPont's Aramid Kevlar material

is a synthetic polymer. Although these fibers may be

readily woven into fabrics, they have poor compression

properties that limit their use to internal ducts,

nonstructural access covers, fairings, and lightly loaded

helicopter skins.

BORON.--Boron fibers are made by chemical

vapor deposition (deposits) of boron onto a tungsten

wire 0.0005" in diameter. Boron fibers have a high

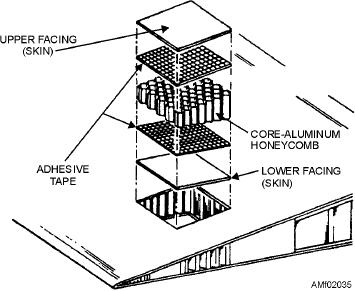

Figure 2-35.--Sandwich construction.

bending stiffness, and cannot be easily woven into cloth

or used for complex contoured parts.

alloy core, sandwiched between aluminum alloy sheets,

Construction

called "facings." The facings are bonded to the

lightweight aluminum core with a suitable adhesive so

Laminate construction consists of skin and

as to develop a strength far greater than that of the

substructures that are manufactured by laminating plies

components themselves when used alone.

of preimpregnated material (prepreg). Sandwich

construction parts used on naval aircraft can be divided

Another type of structural sandwich construction

into two broad classes: (1) radomes and (2) structural.

consists of a low-density balsa wood core combined

with high-strength aluminum alloy facings bonded to

LAMINATE CONSTRUCTION.--Prepreg is

each side of the core. The grain in the balsa core runs

the basic building block of advanced composites. It

perpendicular to the aluminum alloy facings, and the

consists of fibers preimpregnated with partially cured

core and aluminum facings are firmly bonded together

matrix material. These plies of prepreg are cut to the

under controlled temperatures and pressures.

proper size and shape and stacked in specific fiber

orientation. This stack up is then fully cured using heat

The facings in this type of construction carry the

and pressure. Excess resin bled during the cure bonds

major bending loads, and the cores serve to support the

the plies together to form a solid laminate.

facings and carry the shear loads. The outstanding

characteristics of sandwich construction are strength,

SANDWICH CONSTRUCTION.--The first

rigidity, lightness, and surface smoothness.

class, radomes, is a reinforced plastic sandwich

construction designed primarily to permit accurate and

Q2-42.

What type of plastic will soften when heated

dependable functioning of the radar equipment.

and harden when cooled?

The second class, referred to as structural

Q2-43.

What type of plastic will harden when it is

sandwich, normally has either metal or reinforced

heated?

plastic facings on cores of aluminum or balsa wood.

Q2-44.

Plastic sheets should be stored in a bin and

This material is found in a variety of places, such as

must be tilted at least how many degrees from

wing surfaces, decks, bulkheads, stabilizer surfaces,

vertical?

ailerons, trim tabs, access doors, and bomb bay doors.

Q2-45.

What are the three types of advanced com-

Figure 2-35 shows one type of sandwich

posites used on naval aircraft?

construction that uses a honeycomb-like aluminum

2-43