Laminated transparent plastics are well suited to

Transparent plastics, reinforced plastics, and

pressurized applications in aircraft because of their

composite materials are common materials used in

shatter resistance, which is much higher than that of the

aircraft construction. Sandwich construction is used for

stretched solid plastics.

radomes as well as for structural areas where strength

and rigidity are important. Laminate construction is

Stretched acrylic is a thermoplastic conforming to

also used in aircraft construction.

Military

Specification

MIL-P-25690.

This

specification covers transparent, solid, modified acrylic

TRANSPARENT PLASTICS

sheet material having superior crack propagation

resistance (shatter resistance, craze resistance, fatigue

Transparent plastic materials used in aircraft

resistance) as a result of proper hot stretching.

canopies, windshields, and other transparent enclosures

may be divided into two major classes, or groups,

Stretched acrylic is prepared from modified acrylic

depending on their reaction to heat. They are the

sheets, using a processing technique in which the sheet

thermoplastic materials and the thermosetting

is heated to its forming temperature and then

materials.

mechanically stretched so as to increase its area

approximately three or four times with a resultant

Thermoplastic materials will soften when heated

decrease in its thickness. Most of the Navy's high-speed

and harden when cooled. These materials can be heated

aircraft are equipped with canopies made from

until soft, formed into the desired shape, and when

stretched acrylic plastic.

cooled, will retain this shape. The same piece of plastic

can be reheated and reshaped any number of times

Identification

without changing the chemical composition of the

material.

Most transparent plastic sheet used in naval aircraft

is manufactured in accordance with various military

Thermosetting plastics harden upon heating, and

specifications, some of which are listed in table 2-6.

reheating has no softening effect. They cannot be

Individual sheets are covered with a heavy masking

reshaped after once being fully cured by the application

paper on which the specification number appears. In

of heat. These materials are rapidly being phased out in

addition to serving as a means of identification, the

favor of stretched acrylic, a thermoplastic material.

masking paper helps to prevent accidental scratching of

Transparent plastics are manufactured in two forms

the plastic during storage and handling.

of material--solid (monolithic) and laminated.

Identification of unmasked sheets of plastic is often

Laminated plastic consists of two sheets of solid plastic

difficult; however, the following information may serve

bonded to a rubbery inner layer of material similar to

as an aid. MIL-P-8184, a modified acrylic plastic, has a

the sandwich materials used in plate glass.

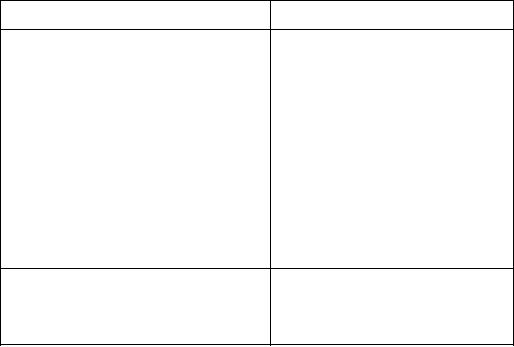

Table 2-6.--Transparent Plastics

Type

Specification No.

Solid Thermoplastic

Thermoplastic

Heat-resistant acrylic

MIL-P-5425

Modified acrylic

MIL-P-8184

Stretched modified

MIL-P-25690

acrylic (8184)

Thermosetting

Polyester craze

MIL-P-8257

resistant

Laminated

Laminated modified

MIL-P-25374

acrylic (8184)

2-40