load of 10 kilograms is applied before the lever is

In addition to the C and B scales, there are other

tripped. This preliminary load is called the "minor

setups for special testing. The scales, penetrators, major

load." The minor load is 10 kilograms regardless of the

loads, and dial numbers are listed in table 2-4. The dial

scale setup. When the machine is set up properly, it

numbers in the outer circle are black, and the inner

automatically applies the 10-kilogram load.

numbers are red.

The metal to be tested in the Rockwell tester must

The Rockwell tester is equipped with a weight pan,

be ground smooth on two opposite sides and be free of

and two weights are supplied with the machine. One

scratches and foreign matter. The surface should be

weight is marked in red. The other weight is marked in

perpendicular to the axis of penetration, and the two

black. With no weight in the weight pan, the machine

opposite ground surfaces should be parallel. If the

applies a major load of 60 kilograms. If the scale setup

specimen is tapered, the amount of error will depend on

calls for a 100-kilogram load, the red weight is placed

the taper. A curved surface will also cause a slight error

in the pan. For a 150-kilogram load, the black weight is

in the hardness test. The amount of error depends on the

added to the red weight. The black weight is always

curvature-the smaller the radius of curvature, the

used in conjunction with the red weight; it is never used

greater the error. To eliminate such error, a small flat

alone.

should be ground on the curved surface if possible.

Practically all testing is done with either the

B-scale setup or the C-scale setup. For these scales, the

Riehle Tester

colors may be used as a guide in selecting the weight (or

weights) and in reading the dial. For the B-scale test,

The Riehle hardness tester is a portable unit that is

use the red weight and read the red numbers. For a

designed for making Rockwell tests comparable to the

C-scale test, add the black weight to the red weight and

bench-type machine. The instrument is quite universal

read the black numbers.

in its application, being readily adjustable to a wide

range of sizes and shapes that would be difficult, or

In setting up the Rockwell machine, use the

impossible, to test on a bench-type tester.

diamond penetrator for testing materials that are known

to be hard. If in doubt, try the diamond, since the steel

Figure 2-31 shows the tester and its proper use. It

ball may be deformed if used for testing hard materials.

may be noted that the adjusting screws and the

If the metal tests below C-22, then change to the steel

penetration indicator are set back some distance from

ball.

the penetrator end of the clamps. This makes it

practicable to use the tester on either the outside or

Use the steel ball for all soft materials--those

inside surface of tubing, as well as on many other

testing less than B-100. Should an overlap occur at the

applications where the clearance above the penetrator

top of the B scale and the bottom of the C scale, use the

or below the anvil is limited. The indicator brackets are

C-scale setup.

arranged so that it is possible to turn the indicators to

Before the major load is applied, the test specimen

any angle for greater convenience in a specific

must be securely locked in place to prevent slipping and

application, or to facilitate its use by a left-handed

to properly seat the anvil and penetrator. To do this, a

operator. Adjustment of the lower clamp is made by the

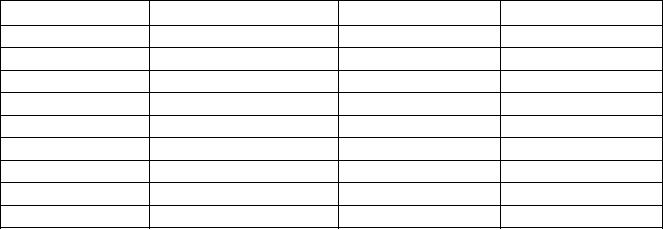

Table 2-4.--Standard Rockwell Hardness Scales

Scale symbol

Penetrator

Major load (kg.)

Dial number

A

Diamond

60

Black

B

1/16-inch ball

100

Red

C

Diamond

150

Black

D

Diamond

100

Black

E

1/8-inch ball

100

Red

F

1/16-inch ball

60

Red

G

1/16-inch ball

150

Red

H

1/8-inch ball

60

Red

K

1/8-inch ball

150

Red

2-36