Q2-30.

At what temperature does aluminum alloy

become a liquid form?

Q2-31.

What term is defined as the eating away or

pitting of the surface or the internal structure

of a metal?

Q2-32.

What property allows two metals to be

welded, brazed, or soldered?

Q2-33.

What are the three basic metal working

processes?

Q2-34.

What type of metal contains iron as its

principal constituent?

Q2-35.

What are the two most commonly used

methods of hardness testing?

Q2-36.

What are the two classes of wrought alloys?

Q2-37.

What type of metal is used in the construction

of fire walls and fuselage skin adjacent to the

engine exhaust outlet?

HARDNESS TESTING

LEARNING

OBJECTIVES:

Identify

hardness testing methods. Identify related

testing equipments and their operation.

Hardness testing is a method of determining the

results of heat treatment as well as the state of a metal

prior to heat treatment. Since hardness values can be

tied in with tensile strength values and, in part, with

wear resistance, hardness tests are an invaluable check

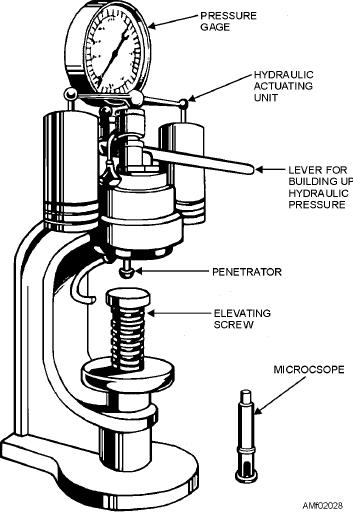

Figure 2-28.--Brinell hardness tester.

of heat-treatment control and of material properties.

Practically all hardness testing equipment now in

service use the resistance to penetration as a measure of

hardness.

applied for 30 seconds. In order to produce equilibrium,

this period may be increased to 1 minute for extremely

TEST EQUIPMENT

hard steels. The load is applied by means of hydraulic

pressure. The hydraulic pressure is built up by a hand

Included among the better known bench-type

pump or an electric motor, depending on the model of

hardness testers are the Brinell and the Rockwell. Also

tester. A pressure gauge indicates the amount of

included are three portable type hardness testers--the

pressure. There is a release mechanism for relieving the

Riehle, the Barcol, and the Ernst--which are all being

pressure after the test has been made, and a calibrated

used by maintenance activities.

microscope is provided for measuring the diameter of

the impression in millimeters. The machine has various

Brinell Tester

shaped anvils for supporting the specimen and an

elevating screw for bringing the specimen in contact

The Brinell hardness tester, shown in figure 2-28,

with the ball penetrator. There are attachments for

uses a hardened spherical ball, which is forced into the

special tests.

surface of the metal. The ball is 10 millimeters (0.3937

To determine the Brinell hardness number for a

inch) in diameter. A pressure of 3,000 kilograms (6,600

metal, the diameter of the impression is first measured,

pounds) is used for ferrous metals and 500 kilograms

using the calibrated microscope furnished with the

for nonferrous metals. Normally, the load should be

2-34