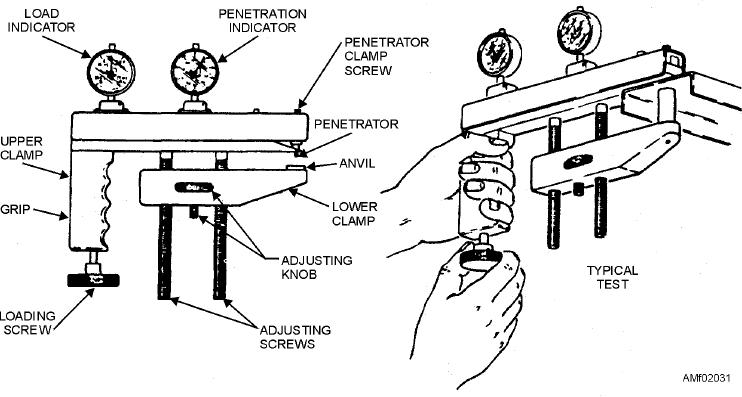

Figure 2-31.--Riehle portable hardness tester.

The hardness reading is based on the measurement

small knurled knob below the clamp. The larger

of the additional increment of penetration produced by

diameter knob, extending through the slot in the side of

applying a major load after an initial penetration has

the clamp, is used for actual clamping.

been produced by the minor load. In reporting a

Each Riehle tester is supplied with a diamond

hardness number, the number must be prefixed by the

penetrator and a 1/16-inch ball penetrator. The ball

letter indicating the scale on which the reading was

penetrator should not be used on materials harder than

obtained.

B-100 nor on a load heavier than 100 kilograms. This is

to avoid the danger of flattening the ball.

Removal and Replacement of a Penetrator

The diamond penetrator, when used with a

The penetrator is retained in the tester by means of

150-kilogram load, may be used on materials from the

a small knurled clamp screw extending from the top of

hardest down to those giving a reading of C-20.

the upper clamp. To remove a penetrator, there should

When the expected hardness of a material is

be at least 2 or 3 inches of space between the upper and

completely unknown to the operator, it is advisable to

lower clamps so that one hand can be placed

take a preliminary reading on the A scale as a guide in

underneath the upper clamp to catch the penetrator

selecting the proper scale to be used.

when it is released. Two or three turns of the clamp

screw will release the penetrator. The two contact pins

Testing Procedures

that extend through the penetrator on either side of the

point are retained in the tester when the penetrator is

The basic procedures for making a test with the

removed.

Riehle tester are as follows:

To replace a penetrator, it must be turned so that the

1. Apply a minor load of 10 kilograms.

flat side faces the clamp screw, and the locating pin on

2. Set the penetration indicator to zero.

the penetrator is in line with the slot provided to take the

pin. The contact pins should be guided into their

3. Apply a major load of 60, 100, or 150

respective holes through the penetrator. With the

kilograms (depending on the scale), and then reduce the

penetrator in place, it should then be clamped securely

load back to the initial 10-kilogram load.

by turning the clamp screw. Before you make an actual

4. Read the hardness directly on the penetration

test, one or two preliminary tests should be made to

indicator.

properly seat the penetrator.

2-37