Barcol Tester

The Barcol hardness tester, shown in figure 2-32, is

a portable unit designed for testing aluminum alloys,

copper, brass, and other relatively soft materials.

Approximate range of the tester is 25 to 100 Brinell.

The unit can be used in any position and in any space

that will allow for the operator's hand. The hardness is

indicated on a dial conveniently divided in 100

graduations.

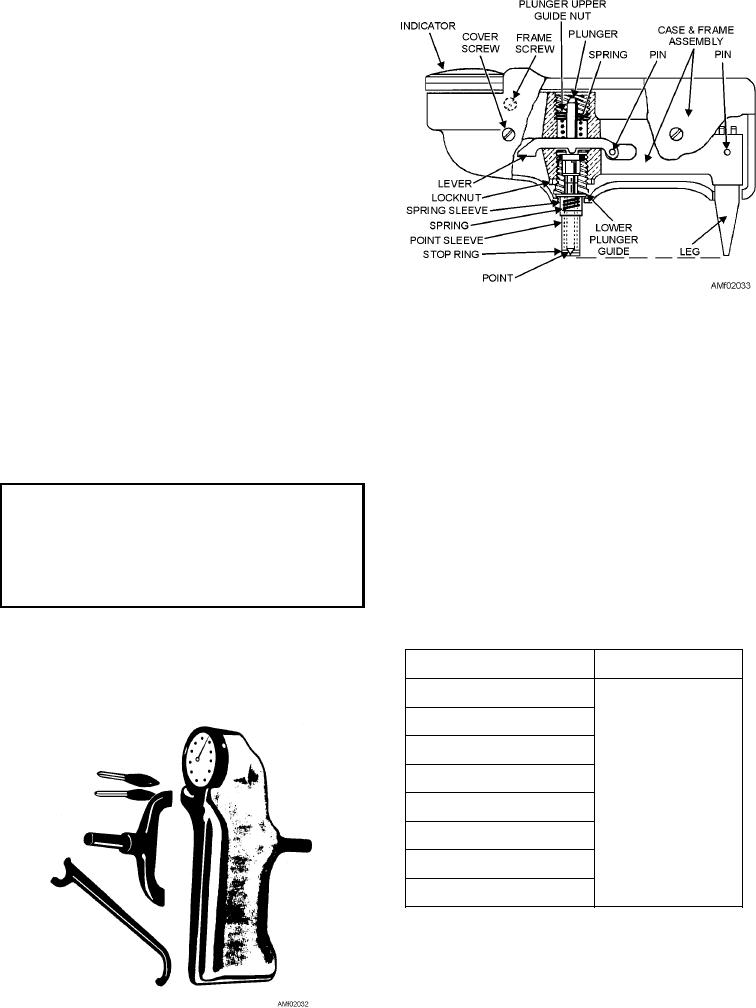

Figure 2-33 is a cutaway drawing of the tester,

showing the internal parts and their general

arrangement within the case.

The lower plunger guide and point are accurately

ground so that attention need be given only to the

proper position of the lower plunger guide within the

Figure 2-33.--Cutaway of Barcol tester.

frame to obtain accurate operation when a point is

replaced.

plane. For permanent testing of this type, the leg may be

The frame, into which the lower plunger guide and

removed and washers inserted, as shown in the

spring-tensioned plunger are screwed, holds the point

drawing. The point should always be perpendicular to

in the proper position. Adjustment of the plunger upper

the surface being tested.

guide nut, which regulates the spring tension, is made

when the instrument is calibrated at the factory.

The design of the Barcol tester is such that

operating experience is not necessary. It is only

necessary to exert a light pressure against the

instrument to drive the spring-loaded indenter into the

CAUTION

material to be tested. The hardness reading is instantly

The position of this nut should not be changed.

indicated on the dial. Several typical readings for

Any adjustment made to the plunger upper guide nut

aluminum alloys are listed in table 2-5. The harder the

will void the calibrated settings made at the factory.

material, the higher the Barcol number.

Table 2-5.--Typical Barcol Readings for Aluminum Alloys

The leg is set for testing surfaces that permit the

lower plunger guide and the leg plate to be on the same

Alloy and temper

Barcol number

plane. For testing rivets or other raised objects, a block

1100-0

35

may be placed under the leg plate to raise it to the same

3003-0

42

3003-1/2H

56

2024-0

60

5052-0

62

5052-1/2H

75

6061-T

78

2024-T

85

To prevent damage to the point, avoid sliding or

scraping when it is in contact with the material being

tested. If the point should become damaged, it must be

replaced with a new one. No attempt should be made to

grind the point.

Figure 2-32.--Barcol portable hardness tester.

2-38