The correct procedures for using the Ernst tester are

Each tester is supplied with a test disc for checking

as follows:

the condition of the point. To check the condition of the

point, press the instrument down on the test disc. When

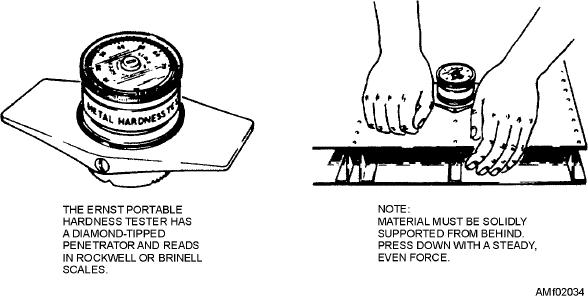

1. Solidly support the metal being tested by

the downward pressure brings the end of the lower

placing a bucking bar behind the metal. This will

plunger guide against the surface of the disc, the

minimize flexing of the metal and yield a more accurate

indicator reading should be within the range shown on

reading of hardness.

the test disc.

2. The handgrip must be pressed down with a

To replace the point, remove the two screws that

steady, even force to ensure accurate readings.

hold the halves of the case together. Lift out the frame,

3. Press down until the fluid column has stopped

remove the spring sleeve, loosen the locknut, and

moving. The hardness value is given at the point where

unscrew the lower plunger guide, holding the point

the fluid column has stopped moving on the scale.

upward so that the spring and plunger will not fall out of

place. Insert the new point and replace the lower

As with other portable testers of similar type, the

plunger guide, screwing it back into the frame. Adjust

material must be smooth and backed up so there will be

the lower plunger guide with the wrench that is

no tendency to sag under the load applied on the tester.

furnished until the indicator reading and the test disc

The test block supplied with each tester should be used

average number are identical. After the lower plunger

frequently to check its performance.

guide is properly set, tighten the locknut to keep the

Q2-38.

What measurement must be taken to

lower plunger guide in place. This adjustment should

determine the Brinell number of a metal?

be made only after installing a new point; any

readjustment on a worn or damaged point give

Q2-39.

How does a Rockwell tester measure the

erroneous readings.

hardness of a metal?

Q2-40.

The Riehle tester is designed for making tests

Ernst Tester

comparable to what bench type machine?

The Ernst tester is a small versatile tool that

Q2-41.

What hardness tester is used for testing

requires access to only one side of the material being

aluminum alloys, copper, brass, and other

tested. There are two models of the tester--one for

soft metals?

testing hardened steels and hard alloys and one for

testing unhardened steels and most nonferrous metals.

NONMETALLIC MATERIALS

It has a diamond point penetrator, and it is read directly

from the Rockwell A or B or the Brinell scales,

LEARNING OBJECTIVES: Identify the

depending on the model used. Figure 2-34 shows the

properties of nonmetallic materials used in

Ernst portable hardness tester and its proper use.

aircraft construction. Identify the properties of

composite materials used in aircraft con-

struction.

Figure 2-34.--Ernst portable hardness tester.

2-39