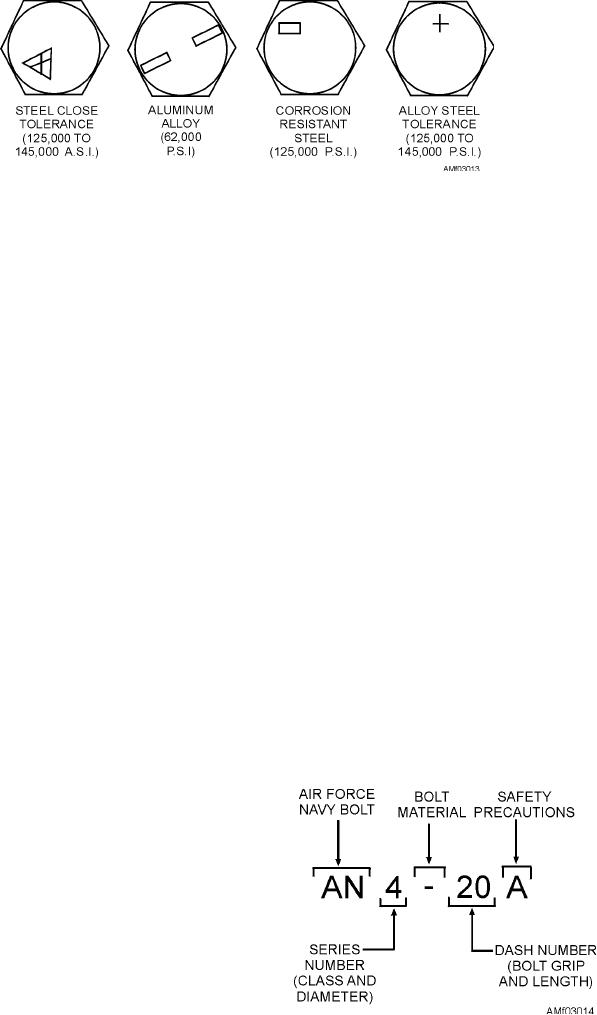

Figure 3-13.--Bolt head markings.

which they are manufactured. Figure 3-13 shows the

This permits higher torque to be applied with less

tops of several hex-head bolts, each marked to indicate

tendency for the driver to slip or cam out of the slots.

the type of bolt material.

View F shows an external-wrenching head that has

a washer face under the head to provide an increased

BOLT IDENTIFICATION.--Unless current

bearing surface. The 12-point head gives a greater

directives specify otherwise, every unserviceable bolt

wrench gripping surface.

should be replaced with a bolt of the same type. Of

course, substitute and interchangeable items are

View G shows a hi-torque style driving slot. This

sometimes available, but the ideal fix is a bolt-for-bolt

single slot is narrower at the center than at the outer

replacement. The part number of a needed bolt may be

portions. This and the center dimple provide the slot

obtained by referring to the illustrated parts breakdown

with a bow tie appearance. The recess is also undercut

(IPB) for the aircraft concerned. Exactly what this part

in a taper from the center to the outer ends, producing

number means depends upon whether the bolt is AN

an inverted keystone shape. These bolts must be

(Air Force-Navy), NAS (National Aircraft Standard),

installed with a special hi-torque driver adapter. They

or MS (Military Standard).

must also be driven with some type of torque-limiting

or torque-measuring device. Each diameter of bolt

AN Part Numbers.--There are several classes of

requires the proper size of driver for that particular bolt.

AN bolts, and in some instances their part numbers

The bolts are available in standard and reduced

reveal slightly different types of information. However,

100-degree flush heads. The reduced head requires a

most AN numbers contain the same type of

driver one size smaller than the standard head.

information.

BOLT THREADS.--Another structural feature in

Figure 3-14 shows a breakdown of a typical AN

which bolts may differ is threads. These usually come

bolt part number. Like the AN rivets discussed earlier, it

in one of two types: coarse and fine. The two are not

starts with the letters AN. Next, notice that a number

interchangeable. For any given size of bolt there is a

follows the letters. This number usually consists of two

different number of coarse and fine threads per inch.

digits. The first digit (or absence of it) shows the class

For instance, consider the 1/4-inch bolts. Some are

of the bolt. For instance, in figure 3-14, the series

called 1/4-28 bolts because they have 28 fine threads

number has only one digit, and the absence of one digit

per inch. Others have only 20 coarse threads per inch

and are called 1/4-20 bolts. To force one size of threads

into another size, even though both are 1/4 of an inch,

can strip the finer threads or softer metal. The same

thing is true concerning the other sizes of bolts;

therefore, make certain that bolts you select have the

correct type of threads.

BOLT MATERIALS.--The type of metal used in

an aircraft bolt helps to determine its strength and its

resistance to corrosion. Therefore, make certain that

material is considered in the selection of replacement

bolts. Like solid shank rivets, bolts have distinctive

Figure 3-14.--AN bolt part number breakdown.

head markings that help to identify the material from

3-8