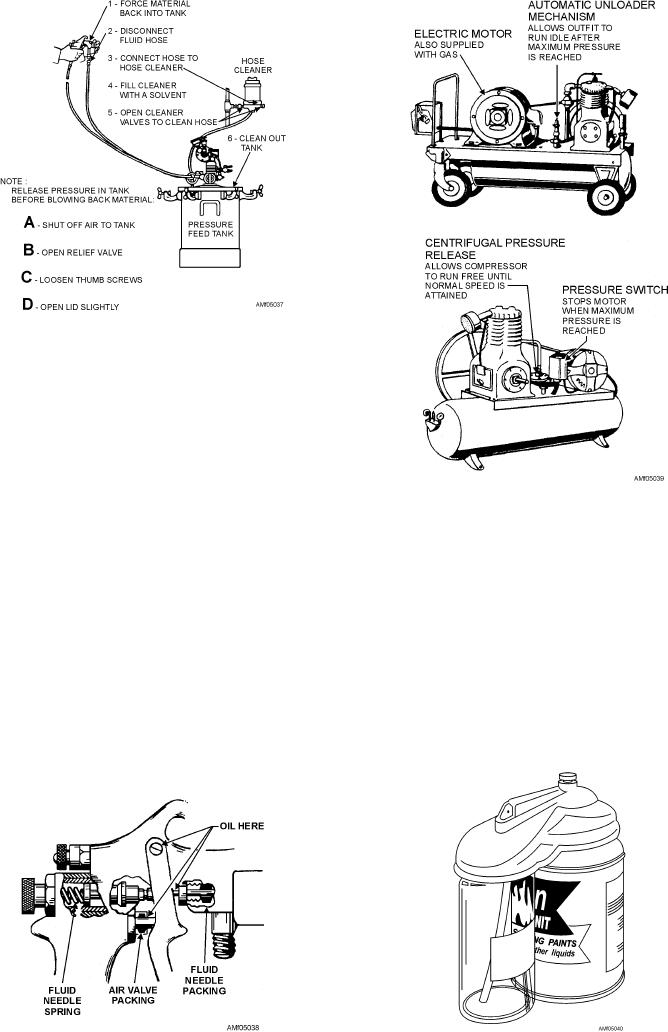

Figure 5-37.--Cleaning pressure-feed spray gun.

trigger. The cloth forces the spray material back into the

pressure tank (fig. 5-37). Remove the fluid hose from

the gun and the pressure tank. Attach a hose cleaner to

the hose and run thinner or suitable solvent through it.

Clean the air cap by using the same method as the

suction gun air cap.

Figure 5-39.--Air compressors.

NOTE: Do not immerse an entire spray gun in

cleaning materials, such as cleaning solvents and

compressors--a portable unit and a stationary unit.

thinners. These materials dissolve the oil from leather

Both types are commonly used. The portable unit

packings and cause the gun to have an unsteady spray.

consists of an electric or gasoline engine, compressor,

storage tank, automatic unloader mechanism, wheels,

The gun, fluid needle packing, air valve stem, and

and a handle. The stationary unit consists of an electric

trigger bearing screw require frequent lubrication. You

motor, compressor, storage tank, centrifugal pressure

should remove the fluid needle packing before using

release, pressure switch, and mounting feet.

the gun and soften it with oil. The fluid needle spring

should be coated with grease according to the

In addition to the standard spray equipment, special

manufacturer's instructions. See figure 5-38.

types have been developed for the occasional or small

touchup job. There are many types available. Figure

Air Compressors

5-40 shows one that consists of a self-contained power

unit with an attached spray bottle (container). The

To use a spray gun, you need a source of

compressed air. Figure 5-39 shows two types of air

Figure 5-38.--Spray gun lubrication points.

Figure 5-40.--Spray kit self-pressurized.

5-35