essential features include the power unit with a

push-button spray cap on the top and on the bottom, and

a screw lid that attaches to the container. A dip tube

extends from the bottom of the power unit into the

sealant. The power unit contains the propellant.

Air Regulators

The air regulator (transformer) is used to regulate

the amount of pressure to the spray gun and to clean the

air. The air delivered to the regulator always contains

some oil from the compressor, some water caused by

condensation, and many particles of dirt and dust.

Air regulators are equipped with a pressure valve

and pressure regulating screw to regulate the pressure

delivered to the spray gun. They also prevent pressure

fluctuations. The air must pass through a sack or

cleaner before it leaves the regulator. This cleaner is

contained in the long cylindrical part of the regulator

and should be drained daily. Air regulators are also

equipped with two gauges. One shows the pressure on

the main line while the other shows the pressure to the

spray gun.

SPRAY GUN TECHNIQUE

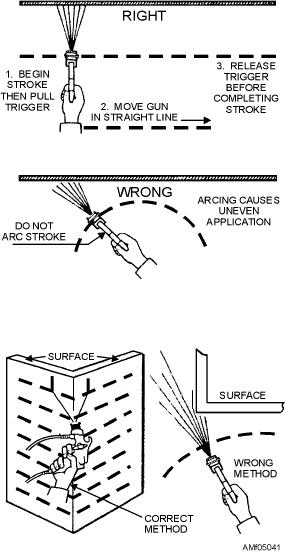

Proper spray gun technique reflects knowledge of

the equipment and experience. The spray gun should be

held so the spray is perpendicular to the area to which

Figure 5-41.--Correct and incorrect methods of spraying.

the finish is being applied. You should ensure that the

perpendicular to the surface. Avoid pivoting and

prescribed gun-to-work distance is maintained.

circular movements of the wrist or forearm. These may

A distance of 6 to 10 inches from the gun to the

bring the gun closer to the surface.

work should be maintained when you are spraying

It is important to trigger the gun in order to avoid an

epoxy-polyamide and polyurethane finishes. The gun

uneven coat at the beginning and end of a stroke.

should be held 8 to 10 inches from the work for lacquer

Triggering is the technique of starting the gun moving

and 6 to 8 inches for enamels. For a narrow pattern, the

toward the area to be sprayed before the trigger is pulled

gun is held at the farther distances (10 inches for

and continuing the motion of the gun after the trigger

epoxy-polyamide and polyurethane, 10 inches for

has been released.

lacquer, and 8 inches for enamels).

You should avoid too much overlapping on each

A distance of less than 6 inches is undesirable

pass of the gun because an uneven coat will result. The

because the paint will not atomize properly, and an

rate of the stroke should produce a full, wet, even coat.

orange peel will result. A distance of more than

Once the job is started, it must be completed without

10 inches is equally undesirable. Dried particles of

stopping.

paint will strike the surface and cause dusting of the

finish. Examples of correct and incorrect spray gun

Spray Gun Adjustments

techniques are shown in figure 5-41.

The distance the spray gun is held from the work is

Figure 5-42 shows the principal parts of a typical

important; however, there are other factors to consider.

spray gun. The spreader adjustment dial is used to

The manner in which the gun is held and operated is

adjust the width of the spray pattern. When you turn the

also important. See figure 5-41. You should move your

dial to the right, a round pattern is obtained. When you

arm and body with the gun to keep the spray

turn to the left, a fan-shaped pattern results.

5-36