engages in a groove in a gas-operated piston installed in

and prevents the delay mechanisms from operating. As

a housing attached to the lower part of the unit body.

altitude decreases, the capsule peg retracts and allows

The piston is held in position by a frangible disc.

the mechanism to function.

When the RH multipurpose initiator cartridge fires

IMPULSE CARTRIDGE.--The impulse car-

during ejection, gas pressure from the cartridge enters

tridge CCU-102/A consists of a cylindrical brass body

the piston housing and moves the piston upwards,

containing two output charge chambers separated by a

rupturing the frangible disc and allowing the ratchet to

central connecting gas gallery. The upper end of the

pivot clear of the rack assembly's slotted end. When the

cartridge has two electrical igniters and is electrically

altitude is low enough that the barostat is not restraining

initiated by signals from the electronic sequencer--a

the mechanism, the rack assembly will rise under the

primary signal to initiate the cartridge and a backup

action of its spring, governed by the delay mechanism.

signal through the second connector to provide system

After the delay has elapsed, the rack disengages from

redundancy. The lower end is initiated by the delay

the gear train and the firing pin rises rapidly to strike the

mechanism firing pin striking the percussion cap.

cartridge. If the cartridge has not previously been fired

Output charge initiated at either end will crossfire, via

electrically by the sequencer, the gas produced by the

the gas gallery, to ignite the output charge in the other

cartridge passes out of the BRU to operate the upper

chamber. The resultant gas pressure is discharged from

and lower harness locks along with the secondary

the center of the cartridge into an annular groove via gas

cartridge in the parachute deployment rocket motor.

ports spaced evenly around the central gas gallery.

TIME-DELAY MECHANISM.--The time-delay

Shoulder Harness Reel

mechanism consists of a spring-loaded rack assembly

in mesh with a gear train controlled by an escapement.

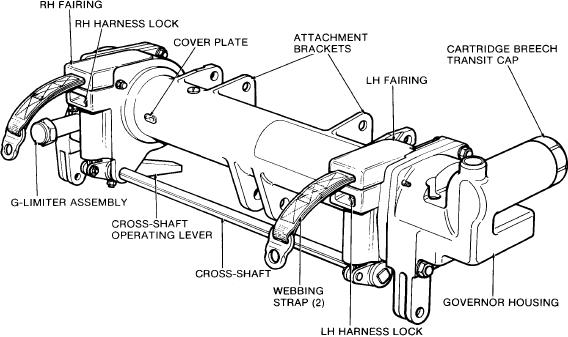

The shoulder harness reel (fig. 2-16) is fitted

The gear train consists of a primary spur and gear, a

horizontally across the front faces of the main beams

secondary spur and gear, an idler wheel, a release

and serves as a center cross-beam for the main beams

wheel, and a release rocker.

assembly as well as a means of securing the upper

harness. It ensures the occupant will be correctly

The rack assembly consists of a rack end screwed

positioned and locked in for ejection. It permits the seat

into a slotted end. The two components are secured

occupant to lean forward and twist around in the seat

together with a locking screw. The upper end of the rack

for maximum visibility, but restrains forward

end is shaped to form a firing pin.

movement in the event of excessive forward

To retain the rack in the cocked position, one face

deceleration. For normal flight operations the shoulder

of a ratchet in the bottom housing engages in the slotted

harness is free to extend and retract as the occupant

end of the rack assembly. Another face of the ratchet

moves in the ejection seat. The shoulder harness control

Figure 2-16.--Shoulder harness reel.

2-15