Q12-20. What is the recommended cleaning method

manual. The tables in the manual do not cover all of the

for removing hard carbon deposits?

possible malfunctions, but should be used as a guide

when performing corrective maintenance.

1.

Use a light grit sandpaper

2.

Use a wire bristle brush

The appropriate portion of the maintenance

3.

Use a decarbonizing solvent

section is referenced when specific step-by-step

4.

Use a scraping tool

instructions are to be followed.

TROUBLESHOOTING

ENCLOSURE TROUBLESHOOTING

LEARNING OBJECTIVE: Identify

Table 12-1 outlines a systematic approach to

procedures for inspecting, testing, and

maintenance. You should note that it is very important

troubleshooting GTC electrical, fuel, bleed air,

that you understand the relationship between the

and lubrication system components.

engine and its enclosure and how they interact. You

must also know the purpose of each system component

At the intermediate maintenance level, you may

before you can systematically analyze the symptoms to

expect to be part of a troubleshooting/maintenance

determine the most likely cause of the problem.

crew, or perhaps even the supervisor. When a

Only those components that are malfunctioning

malfunctioning unit is received, a troubleshooting

crew is assigned to locate the trouble, make the

should be changed. Do not practice shot-gunning,

necessary repairs, and return the equipment to an

which is the removing and replacing of components in

operational status.

the order of their availability or ease of installation,

r ega r d l e s s o f t h e i r l i ke l i h o o d o f b e i n g fa u l t y.

A guide to common engine malfunctions, their

Shot-gunning is a waste of time, and eventually

probable causes, and appropriate remedies is provided

establishes a large inventory of illegal spare parts.

in the maintenance section of the applicable equipment

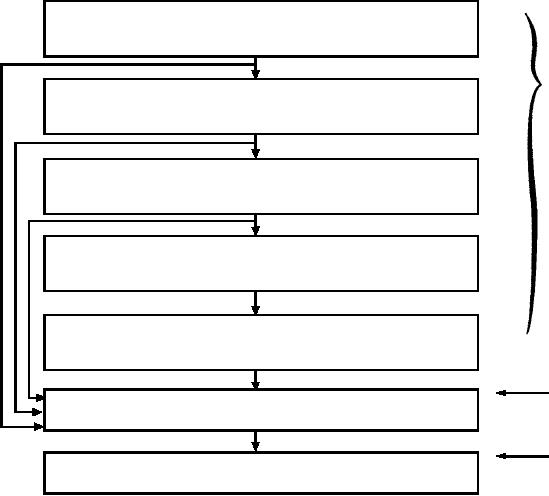

Table 12-1.--Malfunction Correction Procedures

1

TRY TO LOCATE THE TROUBLE BY OBSERVING THE

SYSTEM'S FAULTY OPERATION

TROUBLE-

2

SHOOTING

TRY TO LOCATE THE TROUBLE BY USING EYES, EARS

AND NOSE

3

LOCALIZE THE TROUBLE TO THE FAULTY SECTION BY

TESTING TECHNIQUES

4

LOCALIZE THE TROUBLE TO THE FAULTY STAGE BY

TESTING TECHNIQUES

5

LOCALIZE THE TROUBLE TO THE FAULTY COMPONENT

BY TESTING TECHNIQUES

6

REPAIR

REPLACE OR REPAIR THE DEFECTIVE COMPONENT

7

TEST

PERFORM SYSTEM OPERATION

ASt12001

12-29