assemblies, as well as any needed clamps, brackets,

DRIVE

GEAR

and mounting hardware. The main component of the

PUMP

system is the three-speed centrifugal switch (fig.

HOUSING

12-21). It contains three centrifugally actuated

switches for controlling the sequence of engine

SCAVENGE

OIL INLET

operation. Other components of the system, shown in

FILTER

figure 12-22, are the electrical starter, the control relay,

HOUSING

MANIFOLD

the ignition unit, the igniter plug, the thermocouple,

FITTING

the oil pressure switch, and the start counter.

The system provides the required electrical

TEMPERATURE BULB

starting and control operations through the entire range

OR SWITCH FITTING

of engine operation. A master switch supplies 24 volts

PRESSURE REGULATOR

OIL INLET

CONTROL VALVE

of dc battery power to the engine electrical system.

Upon actuation of the start switch, the electrical starter

EXTERNAL VIEW

motor rotates the engine (through a sprague clutch)

until the engine reaches 35 percent of the governed

FILTER RELIEF VALVE

PUMP

speed; at this time, the centrifugal switch cuts out the

FILTER

starter circuit.

The oil pressure switch contact sets close

sequentially and activate the ignition unit. Then, the

contacts actuate the fuel shutoff and drain solenoid

valve and the start counter.

The ignition unit provides pulsed, high voltage to

the igniter plug until the centrifugal switch cuts out the

ignition circuit at 35 percent of governed speed; at this

speed, combustion is self-sustaining. The load light is

OIL PRESSURE

energized by the centrifugal switch at 95 percent of

REGULATOR

VALVE

PRESSURE

governed speed to indicate the engine is operating at

OIL IN

ADJUST

OIL INLET

sufficient speed to provide bleed air.

SCREW

MANIFOLD

FITTING

FITTING

ASf12020

The centrifugal switch cuts out all circuits and

shuts down the engine at 110 percent of engine

OIL PUMP SCHEMATIC

governed speed by eliminating the ground to the

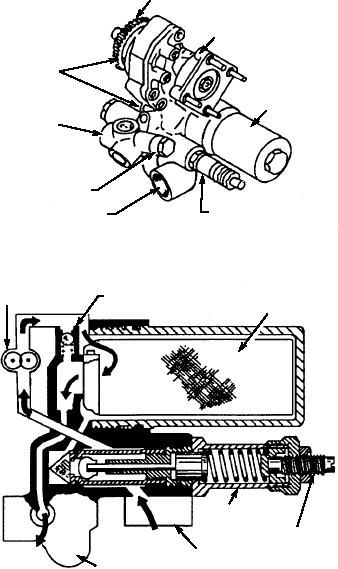

Figure 12-20.--Oil pump assembly.

electrical system holding coil within the control relay.

to mix metered, cooled oil with hot oil, and to cool the

JET AIRCRAFT START UNIT, MODEL

hot oil to operating temperature. The relief valve

A/M47A-4

allows oil to bypass the cooler if pressure increases due

to a failed valve or clogged cooler.

The Model A/M47A-4 jet aircraft start unit (shown

in figs. 12-23 and 12-24) is a complete, self-contained

OIL DRAIN PLUG.--The oil drain plug is

unit that consists of a GTCP-100 gas turbine engine

located at the bottom of the oil tank. The plug allows

mounted in a flyaway assembly enclosed in a

the oil tank to be completely drained of all old or

skid-mounted, weather-resistant enclosure. Some

contaminated oil. This drain plug is accessible through

models of the A/M47A-4 are mounted on trailers for

an enclosure access door. It is important that you

ease of movement from aircraft to aircraft or place to

remember to replace the oil filter element after

place. The A/M47A-4 supplies compressed air at two

completely draining the oil tank and before reservicing

pressure ratios, 5:1 and 3.6:1, for aircraft engine

the tank with fresh oil.

starting and for ac and dc electrical power for operating

aircraft with ac and dc electrical components. The

Electrical System

A/M47A-4 is primarily a shore-based unit; however,

some are used on carriers for maintenance of jet

The electrical system consists of electrical

components, wiring harness assemblies, and lead

engines.

12-24