4

2

3

5

8

9

6

1

7

22

24

23

26

25

21

20

18

10

11

17

12

19

13

16

15

14

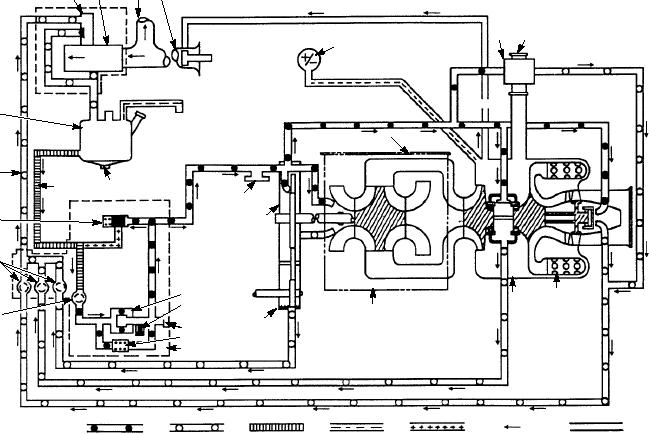

OIL

OIL

OIL

OIL

OIL

DIRECTION

COMPRESSED

PRESSURE

SCAVENGE

SUCTION

VENT

RETURN

OF FLOW OF

AIR

LINE

LINE

LINE

LINE

LINE

MOVEMENT

ASf12019

*1. Oil tank assembly

14. Oil pump assembly

*2. Oil temperature regulator thermostatic bypass valve

15. Filter bypass valve

*3. Oil temperature regulator oil cooler

16. Oil pressure gauge tap

*4. Cooling air duct

*17. Thermoswitch

18. Oil filter

*5. Vane axial cooling fan

*6. Cavity pressure gauge

19. Oil pressure pump

7. Compressor air inlet

20. Oil scavenge pumps

8. Modulating and shutoff valve

21. Relief valve

*22. Scavenge return line

9. Bleed-air outlet duct

*23. Oil pump inlet line

10. Combustion area

*24. Drain plug

11. Turbine section

12. Compressor section

25. Aaccessory drive section

13. Screen

26. Oil pressure switch

*Enclosure furnished equipment

Figure 12-19.--Engine lubrication system schematic.

cooler and the thermostatic temperature control valve.

THERMOSTATIC TEMPERATURE CON-

TROL VALVE.--The oil thermostatic temperature

The cooler assembly is a cylinder that contains a

control valve assembly consists of an inlet valve, an

multitude of small tubes, which extend the full length

outlet valve, and a relief valve. Attached to the oil

of the cylinder. The tubes are supported by perforated

cooler assembly, the control valve bypasses enough

end caps. Hot oil enters one end of the cylinder, flows

hot scavenge oil through the oil cooler to maintain oil

around and between the tubes, and exits at the cylinder

temperature within safe operating limits. The inlet

outlet. Heat imparted to the tubes is radiated to the

valve begins to open when oil temperature reaches

ambient air passing through the tubes. The amount of

operating temperature. Higher temperatures cause the

hot oil passing through the cooler is regulated by the

valve to open further, allowing more oil to enter the

thermostatic temperature control valve.

cooler. The outlet valve opens to the extent necessary

12-23