Vacuum Systems

When the brake is not pressured, excess hydraulic fluid

is returned to the hydraulic reservoir.

Air has weight (atmospheric pressure), and this

The major difference in this system is that it has an

weight results in a pressure of approximately 14.7 psi

open hydraulic system pressurized to 2200 psi with a

at sea level. It is this air pressure that is used in the

600 pound precharge in the accumulator to provide

operation of vacuum brake systems.

braking power even when the engine is not running.

It is impossible to create a perfect vacuum, but by

(Good for a limited number of uses.) The rest of the

pumping air from a container, it is possible to obtain

brake components are similar in appearance and

several pounds per square inch difference in pressure

operation to those of any disc brake system.

between the outside and the inside of the container. If

the container were suddenly opened, outside air

Power Brake Systems

(atmospheric pressure) would rush into the container

The brake system most commonly used on

to equalize the pressure. It is upon this principle that

powered support equipment is the hydraulically

the power cylinder of a vacuum brake system operates.

operated system. However, the increase in size and

There are many varieties of vacuum-powered

weight of aircraft has required heavier and more

brake systems, and it is impossible to cover them all

p ow e r f u l s u p p o r t e q u i p m e n t , e s p e c i a l l y t h e

within the scope of this course. However, the system

aircraft-towing tractors. With this increase in vehicle

most commonly used on support equipment is called

power and weight, it is necessary to have a brake

Hydrovac.

system that is more effective and less strenuous for the

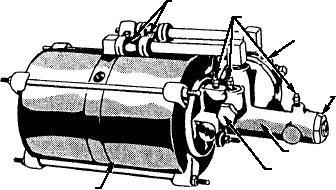

The Hydrovac combines into one assembly a

operator. It was almost impossible for the operator to

hydraulically actuated control valve, a tandem piston

apply sufficient braking action to control a heavy, yet

vacuum power cylinder, and a hydraulic slave cylinder

comparatively small, vehicle. To compensate for this,

(fig. 2-42). The vacuum power brake cylinder is

some hydraulic brake systems are equipped with a

connected hydraulically to both the master cylinder

form of power system to assist the force of the

and the wheel cylinders.

operator's foot in applying the brakes.

The vacuum source for this system, as for all

Power brake systems use the principle of the

vacuum brake systems, is the intake manifold of the

hydraulic brake to operate the wheel brake cylinders

engine. Reciprocating engines, particularly gasoline

and produce braking action. In addition, these systems

engines, generate a substantial vacuum in this area

use the energy of air pressure, either to apply the

except when running at full power. A check valve

necessary pressure to the hydraulic fluid or to assist in

maintains a vacuum within the system, even after the

this application. Atmospheric pressure provides this

engine is stopped, by closing the intake manifold when

energy in some power systems, while a compressor is

the pressure in the manifold rises above the vacuum

required in others. Many of the Navy's aircraft-towing

pressure within the system. A vacuum reservoir is

tractors are equipped with some type of power brake

usually required so that a substantial source of vacuum

system. Some are equipped with a form of

is available. Once air is pumped out of the vacuum

va c u u m - b o o s t s y s t e m , w h i l e o t h e r s u s e a n

air-over-hydraulic system.

reservoir through the intake manifold, the resulting

HOSE CONNECTIONS

BLEEDER SCREWS

CONTROL

VALVE

END

PLUG

SLAVE CYLINDER

VALVE CYLINDER

VACUUM POWER

FITTING PLUG

CYLINDER

ASf02042

Figure 2-42.--Hydrovac vacuum power brake cylinder.

2-34