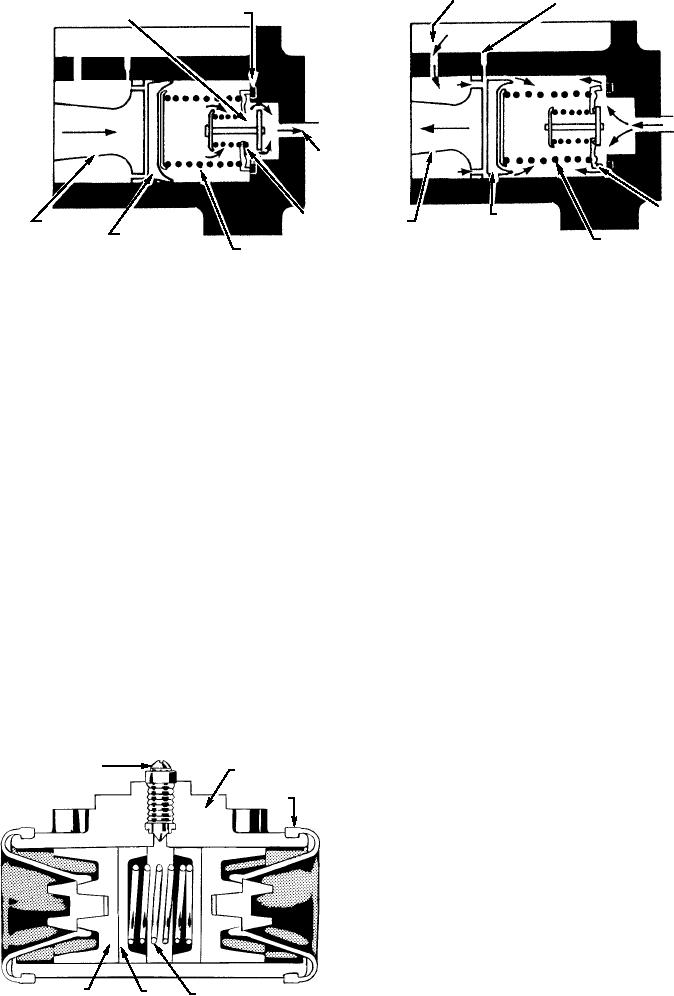

BREATHER

COMPENSATING PORT

CAGE SEAT

PORT

CHECK VALVE

BRAKE

BRAKE

LINE

LINE

VALVE

PRIMARY

CAGE

VALVE

PISTON

PISTON

CUP

SEAT

PRIMARY

RETURN

CUP

RETURN SPRING

SPRING

ASf02038

PRESSURE APPLIED

PRESSURE RELEASED

Figure 2-38.--Hydraulic brake master cylinder--operation of two-way valve.

seal at the wheel cylinder cup packing and prevents air

The two pistons in the cylinder move in opposite

from entering the system.

directions under hydraulic pressure. Through a short

stem, the pistons push the shoes against the drum.

Wheel Cylinder.--The wheel cylinder may be of

These stems are connected directly to the shoes.

almost any design or exterior shape to suit the need, but

all wheel cylinders work on the same basic principle

Rubber cup seals fit tightly in the cylinder bore

and fulfill the requirements of moving the brake shoes

against each piston to prevent the escape of fluid.

into contact with the drum. There are two basic

Between the cups is a light spring to keep the cups in

designs--a single-piston type and a double-piston

position against the pistons. The open ends of the

type, sometimes called uniservo and duoservo

cylinder are fitted with rubber boots to keep out foreign

cylinders, respectively. Different combinations of

matter.

these two types of cylinders are used on different

Brake fluid enters the cylinder from the brake line

models of equipment.

connection between the pistons. A bleeder port and

Figure 2-39 illustrates a double-piston wheel

valve are located at the top of the cylinder between the

cylinder. The single-piston is similar, only smaller

pistons. This provides a means for releasing air from

because it has only one piston. This unit, regardless of

the system.

whether single- or double-piston type, changes the

Various applications of wheel cylinders are used in

applied fluid pressure into mechanical force to move

support equipment, depending upon the

the brake shoes. The wheel cylinder housing, made

m a n u f a c t u r e r 's d e s i g n . S o m e m a y h a v e o n e

from a casting, is bolted to the brake backing plate.

single-piston cylinder or a dual-piston cylinder per

wheel, each operating two shoes. Others may use a

BLEEDER SCREW

CYLINDER

combination of one single and one dual piston or two

HOUSING

dual pistons per wheel. When a dual system is used,

BOOT

each cylinder is mounted diametrically opposite the

other, and each operates one end of two shoes.

I N S P E C T I O N A N D M A I N T E NA N C E . --

Hydraulic brake systems must be inspected at

specified intervals. A visual inspection includes

checking the fluid level in the master cylinder

reservoir, the security of mounting bolts and clamps,

the condition of tubing and hoses, and the entire system

for leaks. When the wheels and drums are removed for

PISTON

ASf02039

CUP

RETURN SPRING

inspection of the brake assemblies, the wheel cylinder

Figure 2-39.--Hydraulic brake wheel cylinder.

should be inspected for leaks. The boots may be pulled

2-30