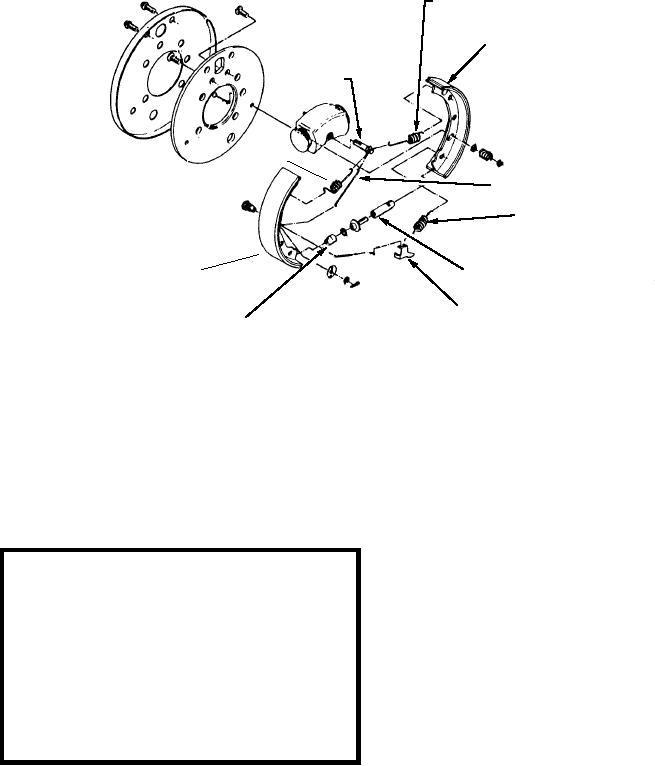

RETURN

SPRING

PRIMARY SHOE

WHEEL CYL.

BOLT

RETURN

SPRING

LINK ADJUSTER (UPPER)

SPRING, AUTOMATIC

ADJUSTER

SECONDARY

SHOE

NUT, PIVOT R.H.

ADJUSTER

ASf02032

NUT, PIVOT L.H.

LEVER

Figure 2-32.--Brake assembly, self-adjusting.

inspections. The interval of these inspections is usually

wheel is locked by the brake shoes, and then back off

specified in the applicable instruction manual and

the star wheel a certain number of notches or until no

maintenance requirements cards (MRCs). An

dragging noise is heard between the drum and the

operational check is usually conducted daily.

shoes.

O n n o n p ow e r e d e q u i p m e n t , t h i s c a n b e

NOTE: Unless thoroughly familiar with the type

accomplished by attempting to move the vehicle with

of brakes to be adjusted, you should carefully follow

the brakes set. Similarly, emergency or parking brakes

the procedures outlined in the manufacturer's service

of powered equipment can be checked by applying

manual.

power to the wheels with the brakes set.

WARNING

A road test is usually conducted for the operational

check of the wheel brakes of powered equipment. The

When working on brakes it is usually necessary to

brakes must stop a moving vehicle in a reasonable

jack up the vehicle. When doing so, be sure to

distance. After the vehicle is stopped, the brake marks

observe these precautions: (1) Place the proper

on the roadway should be inspected to see if there is an

rated jack stands under the vehicle when it is

indication of any one wheel braking more than the

raised. (2) Never work under a unit using a jack

others. If the brakes do not stop the vehicle within the

only. (3) Before using a hydraulic jack, make sure

prescribed distance, are not equalized, grab, or do not

it is filled with fluid and has no apparent leaks. (4)

hold, the necessary adjustments or repairs must be

Aboard ship, tie or chain the unit down while it is

made.

on jack stands.

The wheel brake assembly must be visually

inspected at specified intervals. To do this, you must

BRAKE INSPECTION AND

remove the wheel and brake drum. Clean the dust and

MAINTENANCE

crud out of the assembly, taking care not to breathe the

Frequent brake inspections are necessary to ensure

asbestos dust. You should use an asbestos vacuum

safe operating conditions. Brake inspections are not

cleaner or a wet spray-type cleaner and respirator.

made just to comply with regulations but to ensure

Ensure you meet all EPA, LOCAL COMMAND, and

safety of personnel and equipment. Defective brakes

NAVOSH REQUIREMENTS prior to doing brake

are a contributing factor to many accidents that might

work.

have been avoided with frequent and thorough brake

The brake assembly should be checked for loose or

inspections.

broken brake shoe retracting springs, worn clevis and

Like most components of support equipment,

cotter pins in the brake operating mechanism, and

indications of grease or oil leaks at the wheel bearing

brake assemblies require both operational and visual

2-25