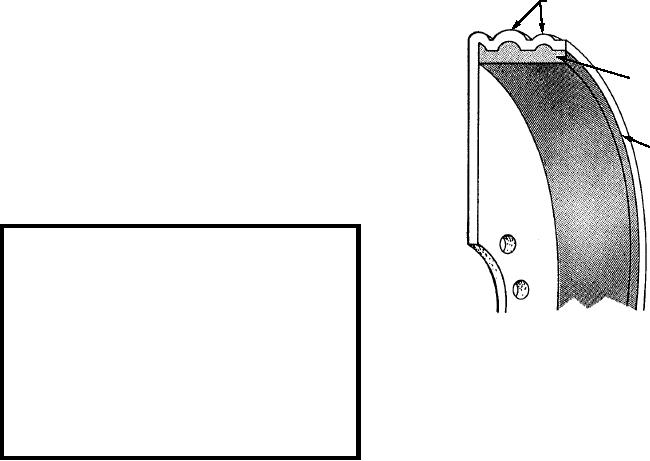

COOLING RIBS

The lining may be secured to the shoes by riveting

or by a bonding process in which the linings are glued

to the shoe. In the bonding process, pressure and heat

are applied to make a secure bond between the lining

CAST IRON

LINER

and the shoe. The bonding process allows the lining to

be worn comparatively thin without danger of cutting

or scarring the drum. When brass rivets are used to

STEEL

secure the lining to the shoe, the lining must be

replaced when it is worn to a specified amount to keep

the rivets from scarring the drum.

WARNING

Many types of linings contain asbestos, and dust

from normal wear may accumulate in the brake

drum assembly. For this reason, special procedures

ASf02031

are followed, including the wearing of a suitable

Figure 2-31.--Sectional view of a brake drum.

respirator, when working on asbestos brakes. Do

not use compressed air to blow out the drum or

When a brake is correctly adjusted, the lining

brake assembly, and use a suitable solvent for

attached to the brake shoes fits evenly against the brake

cleaning parts. Remember that asbestos dust is

drums when the brakes are applied. Also, the lining

treated as hazardous waste.

will be free of the drum when the brakes are released.

The linings must not drag against the drum, yet they

must be near enough to give the proper leverage

BRAKE DRUMS

between the operating mechanism and the friction

surfaces. The backing plate of some brake assemblies

Brake drums are made of pressed steel, cast iron, or

contains small slots for the purpose of checking these

a combination of the two metals. Cast iron drums

clearances with a feeler gauge.

dissipate the heat generated by friction more rapidly

than steel drums, and have a higher coefficient of

Most automobiles and some support equipment

friction with any particular brake lining. However, cast

have a mechanism that automatically adjusts the

iron drums are heavier and are not as strong as steel.

brakes. The adjustment takes place when the brakes

are applied as the vehicle is moving backward. As

Quite often, steel drums have a cast iron liner fused into

the brakes are applied, friction between the primary

them to provide the necessary strength and

shoe and the brake drum forces the primary shoe

heat-dissipating qualities (fig. 2-31). To further add to

against the anchor pin (fig. 2-32). Then, hydraulic

the strength and heat dissipation qualities, cooling ribs

pressure from the wheel cylinder forces the upper

are sometimes used on the outside of the drums.

end of the secondary shoe away from the anchor pin

and downward. This causes the adjuster lever to

BRAKE ADJUSTMENTS

pivot on the secondary shoe so that the lower end of

Due to normal wear of the brake linings, brake

the lever is forced against the sprocket on the

assemblies (except for disc brakes) require periodic

adjuster screw. If the brake shoes have worn enough,

the adjuster screw turns a full tooth. This spreads the

adjustment. Normal wear can result in excessive

lower ends of the brake shoes a few thousandths of an

clearance between the lining and drum and can lead to

inch, or enough to compensate for the shoe wear.

poor and uneven braking. One possible outcome of

poorly adjusted brakes is that during hard braking, one

Some brake assemblies and even autoadjusting

wheel may lock before the others are stopped, causing

brakes require first time adjustment in the same

the driver to lose steering control of the vehicle. It is

manner as nonself-adjusting brakes. Many have a slot

important, therefore, that brake adjustments be made

in the rear of the backing plate to allow a thin blade tool

to provide equal distribution of brake action to all

to turn the star wheel. Brakes with this type of

adjustment require you to turn the star wheel until the

wheels.

2-24