ve h i c l e . T h e c a l i p e r a s s e m b l y, w h i c h r e m a i n s

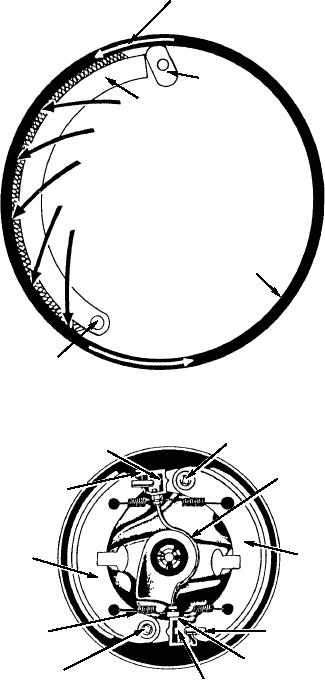

DIRECTION OF

DRUM ROTATION

stationary, attaches to the steering knuckle on the front

wheels or to the rear axle housing on the back wheels.

The disc is usually solid when used on a

CAM

lightweight vehicle and vented (for cooling) on a heavy

SHOE

vehicle. Both sides of the disc are machined to provide

a smooth friction surface. The caliper contains one or

more hydraulic pistons, which cause the brake shoes

(one on either side of the disc) to squeeze the disc in a

viselike manner.

Figure 2-28 illustrates the operation of a typical

disc brake assembly. In actual application, the brake

shoes (friction pads) are held in light contact with the

disc when the brakes are released by a piston return

DRUM

spring.

Some disc brake shoes have telltale tabs that

contact the disc when lining wear has reached a

ASf02024

ANCHOR PIN

predetermined point. This results in a scraping noise

when the vehicle is operated, warning the operator that

Figure 2-24.--Brake shoe self-energizing action.

the brake shoes are badly worn and should be replaced.

Disc brakes require no adjustment. However, you

ANCHOR PIN

PISTON

will occasionally have to add brake fluid to the master

cylinder reservoir, which supplies fluid for the disc

BRAKE LINE

WHEEL

portion of the braking system. This is necessary

CYLINDER

because the piston return springs, by keeping the shoes

against the disc as wear occurs, create a larger cavity

for the fluid in the caliper assembly. A booster

SHOE

SHOE

assembly is often used in disc brake systems, as they

have no self-energizing feature. Some features of the

disc brake make it more desirable than the drum brake;

RETRACTING

STEM

namely, braking action is instantaneous when pressure

SPRING

is applied to the caliper assembly, fading caused by the

ANCHOR

WHEEL

PIN

CYLINDER

heat is eliminated, and the brakes are not affected when

PISTON

ASf02025

water is splashed onto the disc and linings.

Figure 2-25.--Front wheel brake assembly.

SERVICING DISC BRAKES.--Anytime a

This method of anchoring allows the movement of

vehicle with disc brakes is scheduled for maintenance,

the shoes necessary to expand against the drum when

the disc should be inspected for scoring and hard spots.

the shoes are forced against the drum, and the

Slight scoring results from normal braking. A disc that

s e l f - e n e rg i z i n g a c t i o n o f t h e p r i m a r y s h o e i s

is scored less than 0.015 inches can be used without

transmitted through the pivot to the secondary shoe

machining if the overall thickness of the disc is still

(fig. 2-26). Both shoes tend to revolve with the drum

within the manufacturer's specifications. Heavy

and wedge against the drum through the one anchor

scoring or hard spots require the disc to be machined.

pin. The other anchor pin causes a similar action when

The rust ridges that build up as wear occurs are of

the wheel is revolving in the opposite direction.

no concern unless new shoes are to be installed.

Placing new shoes on a disc that has rust ridges causes

Disc Brakes

the shoes to seat on the ridge, resulting in poor braking.

These ridges should be removed by grinding or

The disc brake assembly (fig. 2-27) consists of a

machining prior to installing new shoes. A special

metal disc and caliper assembly. The disc, which is

lathe is normally used for machining discs. However, if

bolted to the wheel hub, rotates with the wheel of the

2-19