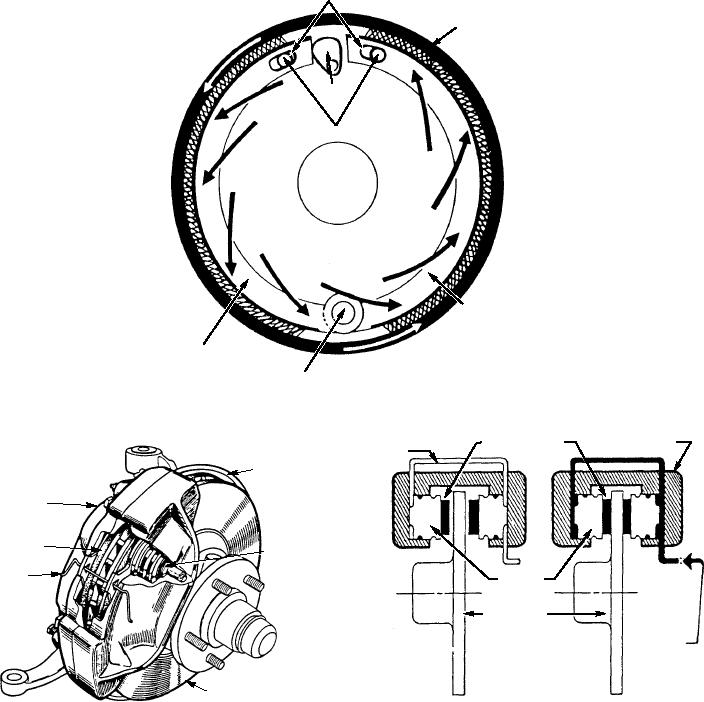

SLOTS

DRUM

CAM

ANCHOR PINS

SECONDARY

SHOE

PRIMARY

SHOE

ASf02026

PIVOT

Figure 2-26.--Primary and secondary brake shoes--self-energizing action.

CONNECTING

CYLINDER

FRICTION PADS

TUBE

SPLASH

SHIELD

CALIPER

SHOE AND

LINING

PISTON

ANTI-RATTLE

SPRING

HYDRAULIC

PRESSURE

BRAKE DISK

FROM

MASTER

CYLINDER

APPLIED

RELEASED

POSITION

POSITION

ASf02027

DISK

ASf02028

Figure 2-28.--Sectional view of a disc brake in released and

applied position.

Figure 2-27.--Disc brake assembly.

indicate a faulty disc, the disc must be machined. If it is

none is available, the metal lathe in the machine shop

worn excessively, it must be replaced.

and a grinding attachment will do the job.

REPLACING DISC BRAKE LININGS.--Disc

A test should be made when shoes are replaced to

brakes have flat linings bonded to a metal plate or pad

determine if the disc has excessive runout (out of

(shoe). The pad is not rigidly mounted inside the

round) or thickness variation. Either condition will

caliper assembly, thus it is said to float. The pads are

cause erratic braking similar to that caused by a warped

held in position by retainers or internal depressions

drum on conventional brakes.

(pockets machined into the caliper).

Runout or wobble of the disc as it rotates must

Figure 2-29 shows a disc brake assembly. To

be checked with a dial indicator. Thickness variation

remove brake pads, raise the front of the vehicle and

is determined by measuring the thickness of the disc

remove the wheels. Next, remove approximately

in at least three places approximately 1 inch from the

two-thirds of the fluid from the master cylinder and

outer edge of the disc. Should either of these tests

2-20