in manual steering. Because of this, wear of the

constructed so that to remove it from the vehicle, one

linkage will normally progress to a dangerous point

or both ends must be disassembled or loosened. The

before the operator typically becomes aware of the

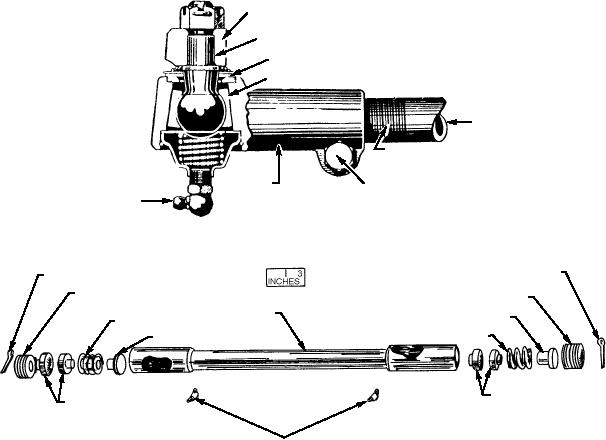

adjusting plug (fig. 2-19) is used to remove any free

problem.

play between the drag link and the connecting parts of

the linkage. Occasionally, adjustment of the plug is

Should hard steering occur, check the pressure

needed to compensate for wear of the ball and seats

of the steering pump to determine if that is the

or weakening of the spring.

problem. Use a suitable pressure gauge to determine

the pressure of the system. Follow the

The tie rod is equipped with a ball-type socket at

manufacturer's procedure, and compare the results

each end to allow for movement of the connecting

to the specifications in the technical manual. If

parts of the steering linkage. These sockets, called

within limits, adjust the pressure by altering spring

TIE ROD ENDS, must be checked for wear or slack.

tension in the relief valve. If the results are not within

The linkage should pivot at the ball socket without

limits and cannot be adjusted, a faulty component is

allowing free movement between the socket and

indicated, and it should be replaced.

ball. A slight drag is considered the optimum

condition of the ball joints. In addition to the flexible

Other Maintenance Procedures

end connections, the linkage is designed so that an

adjustment can be made when performing wheel

Lubrication involves the greasing and oiling that

alignment. The tie rod is normally connected

is performed at the time the entire vehicle is greased.

directly to the steering knuckle or spindle arm and

Figure 2-18 shows the tie rod end grease fitting.

used to transmit the steering effort to the wheel via

Consult the manufacturer's service instructions for

the knuckle or spindle.

the proper lubricant to use.

You can check worn or improperly adjusted

linkage connections by jacking up the front end of the

Depending on the steering arrangement, a drag

vehicle, grasping each wheel (front and rear of the

link or idler arm rod may be used in the linkage to

wheel), and moving the wheel in and out to check for

connect the pitman arm and the remainder of the

excessive movement. At the same time, you can check

steering linkage. This portion of the linkage is usually

KNUCKLE ARM

STUD

DUST SEAL

BALL SOCKET

TIE ROD

ADJUSTING

THREADS

TIE-ROD

END

CLAMP BOLT

LUBRICANT

FITTING

ASf02018

Figure 2-18.--Tie rod end showing clamp bolt and adjusting threads.

COTTER PIN

COTTER PIN

ADJUSTING PLUG

ADJUSTING PLUG

DRAG LINK

SPRING PLUG

SPRING

SPRING

SAFETY PLUG

BALL SEATS

BALL SEATS

ASf02019

LUBRICATION FITTINGS

Figure 2-19.--Drag link assembly--exploded view.

2-14