system should be inspected for signs of rust and

wheel cylinders are the actuators. (An actuator is a

corrosion. Maintenance includes replacement of

device that transforms fluid pressure into mechanical

force to move a mechanism.)

defective parts, servicing with required lubricants,

securing loose clamps and fittings, and straightening

A nonpetroleum-based fluid is normally used in

bent rods and shafts.

the brake systems of support equipment. The

applicable technical manual should be consulted to

Upon replacement of any component, the brakes

ensure that the correct brake fluid is used.

require adjustment to ensure both brakes are applied

equally, that they hold the unit in place when the brakes

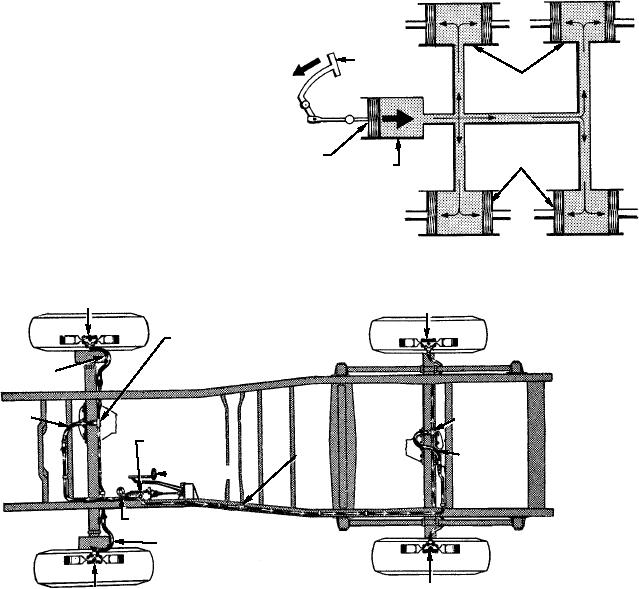

Figure 2-36 shows the operation of a hydraulic

are applied, and that they release fully when the brake

brake system. Depressing the brake pedal moves the

level is in the released position.

piston within the master cylinder, thus developing fluid

pressure. This buildup of pressure forces fluid from the

Hydraulic Brake Systems

master cylinder into the fluid lines and the wheel

cylinders.

A hydraulic brake system is primarily a liquid

connection or coupling between the brake pedal and

Like all liquids, brake fluid for all practical

the individual brake assemblies.

purposes is noncompressible. Therefore, the pressure

originated in the master cylinder is transmitted equally

A P P L I C AT I O N . -- T h e e f f e c t i v e n e s s a n d

to the wheel cylinders. This pressure, applied at the

reliability of hydraulic brake systems have been

wheel cylinders, causes the pistons to move outward.

proven through their extensive use on automobiles for

over 50 years. As a result, hydraulic systems are the

most common systems used for the operation of the

wheel brakes on powered support equipment. The

CE

hydraulic brake systems on some late model

OR

F

BRAKE PEDAL

equipment are provided with a vacuum or air booster.

WHEEL CYLINDERS

The latest hydraulic brake systems used on support

equipment tractors are true high-pressure hydraulic

systems. These systems are powered by engine-driven

MASTER

hydraulic pumps.

CYLINDER

WHEEL CYLINDER

MASTER

PISTON

CYLINDER

COMPONENTS AND OPERATION.--Figure

2-35 shows a typical arrangement of a hydraulic brake

system. The system consists of a master cylinder

connected by tubing and flexible hose to the wheel

ASf02036

cylinders. The master cylinder serves as a fluid

Figure 2-36.--Operation of hydraulic brake system.

reservoir, the system pump, and the control valve. The

FRONT WHEEL CYLINDER -- RIGHT

REAR WHEEL CYLINDER -- RIGHT

BRAKE TUBE FRONT AXLE TEE

FRONT WHEEL

BRAKE HOSE

FRONT AXLE

BRAKE HOSE

BRAKE TUBE

REAR

AXLE TEE

MASTER

CYLINDER

REAR AXLE

TUBE

BRAKE HOSE

UNION

BRAKE PEDAL

SIGNAL LAMP SWITCH

ASf02035

FRONT WHEEL

BRAKE HOSE

REAR WHEEL CYLINDER -- LEFT

FRONT WHEEL CYLINDER -- LEFT

Figure 2-35.--Typical hydraulic brake system.

2-28