Most hydraulic systems are equipped with return

be consulted for adjustment procedures for the pedal

lines between the actuating units and the reservoir. The

linkage. The master cylinder must be serviced and the

fluid circulates from the reservoir, through the supply

system bled before the brakes are ready for service.

lines, through the actuating units, and back to the

However, before this is accomplished, all necessary

reservoir. This allows any air in the system to escape

repairs should be made to the wheel cylinders.

through the reservoir vent during circulations.

Wheel Cylinder Repair.--Wheel cylinders are

Brake hydraulic systems, however, are not

rebuilt in much the same manner as a master cylinder.

equipped with return lines; therefore, there is no means

To do this, it is seldom necessary to remove the

for the air to escape. Air in the system will cause the

cylinder assembly from the brake backing plate.

action of the brake pedal to feel soft and spongy

However, before the cylinder can be repaired, the brake

because air is compressible. The hydraulic brake

assemblies must be removed.

system must be bled to expel this air.

To disassemble a wheel cylinder with two pistons

There are two common methods of bleeding a

(fig. 2-39), pull the boots from the cylinder and push

hydraulic brake system--the pressure method and the

the pistons, cups, and spring out of the cylinder.

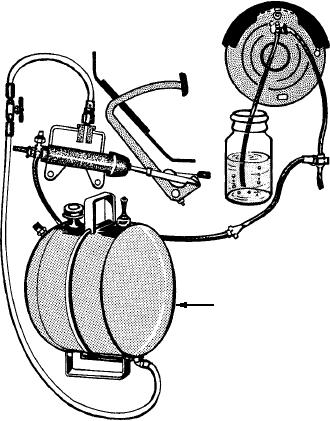

manual method. The pressure method employs a brake

After the parts are removed, clean the cylinder wall

bleeder tank, which delivers fluid under pressure to the

and check for pits and accumulation of rust. A small

master cylinder (fig. 2-40).

quantity of pits or rust at the exact center of the cylinder

Before pressurizing the bleeder tank for use,

should not affect the operation of the wheel cylinder. If

ensure that the tank has an adequate supply of the

the rust or pits are just inside the outermost polished

required type of brake fluid and that the valve on the

areas of the cylinder bore, they must be removed by

discharge line is closed.

honing. Cylinders containing deep pits or scratches

must be replaced.

Manufacturers usually recommend that the master

cylinder reservoir be filled with hydraulic fluid before

After honing a cylinder, remove all the abrasive

connecting the pressure tank. Make sure there is a tight

dust and lubricate the cylinder walls with clean, new

seal between the adapter cap and the master cylinder

hydraulic fluid. The pistons are usually made of

filler port. Then, apply pressure to the master cylinder

aluminum, and unless badly scored, they may be

by opening the valve on the discharge line of the tank.

reused indefinitely. However, they should not be

sanded--only cleaned with an approved solvent or

clean, hydraulic brake fluid.

After the cylinder bore is satisfactorily cleaned and

lubricated, lubricate the cup seals. Insert a cup into the

end of a cylinder. Do not push the cup through the bore.

As soon as the lips of the cup are in the bore, use the

piston to move the cup into place.

Installing the other cup and piston may be more

difficult, since the cup retaining spring will push

against the cup and piston already installed. With one

hand, hold the one piston from pushing out, and with

the other hand, install the spring, cup, and piston. Then,

install the boots and brake shoe links, rods, or slugs.

Install a wheel cylinder clamp or use a cord or wire to

tie a loop around the cylinder to hold the components in

PRESSURE TANK

the cylinder until the brake shoes are installed.

Bleeding Hydraulic Brake Systems.--During

repair of the master brake cylinder or wheel cylinders,

or anytime a brake line is disconnected, air will enter

the hydraulic brake system. Also, when the fluid level

ASf02040

in the reservoir is allowed to become too low, air will

Figure 2-40.--Bleeding hydraulic system--pressure method.

enter the brake lines.

2-32