transmission, the operator selects neutral, reverse, or

DRIVER, and the turbine may be called the RUNNER.

o n e o f s eve r a l r a n g e s o f f o r w a r d s p e e d . T h e

Often the two members are called the FRONT TORUS

transmission automatically shifts from one forward

and the REAR TORUS. (A torus is doughnut-shaped

speed/torque ratio to another based on the rpm of the

and turns on an axis.) You should become familiar with

engine and the speed of the vehicle. The automatic

all these terms so that you can understand the

transmission does not require a manually operated

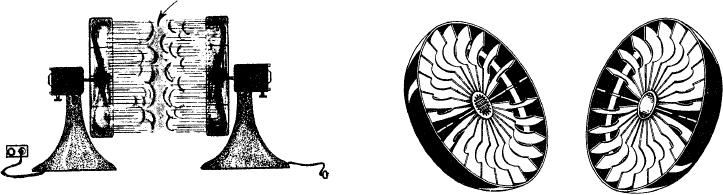

manufacturers' technical manuals. Note that in figure

clutch. All support equipment used by the Navy have

2-49, the pump and turbine are torus-shaped with fins

automatic transmissions.

extending radially from its center.

Most of the fundamentals of hydraulics are put to

The pump of the fluid coupling is connected to the

work in one form or another in the automatic

engine and is rotated by the crankshaft. Usually, the

transmission. Automatic transmissions use such

pump is bolted directly to the flywheel.

hydraulic devices as relief valves, shifter valves,

The turbine is made exactly like the pump, but it is

pressure regulators, governors, and servo pistons. In

connected to the transmission input shaft. The two

most cases, the transmissions are used with fluid

members of the coupling face each other within a

couplings or hydraulic torque converters.

housing that is filled with the driving fluid (generally

oil).

FLUID COUPLINGS

When the pump goes into motion, oil is forced

A fluid coupling, sometimes called a "fluid

outward by centrifugal force around the entire

clutch," is precisely what its name implies. When it is

circumference of the pump and hurled against the

placed between an engine at the power-input end and

blades of the turbine. A continuous flow of oil against

some other mechanism, such as a transmission at the

the turbine blades is necessary to transfer sufficient

output end, it couples the two hydraulically, and there

kinetic energy to keep a vehicle in motion.

is absolutely no mechanical connection between them.

The centrifugal force of the oil as it leaves the

A simple sort of fluid coupling can be made with two

pump gives the oil the velocity it needs. The faster the

electric fans, as shown in figure 2-48. If the fans are

pump operates, the more velocity the oil has when

placed a few inches apart, facing each other, and one

leaving the pump. The design of the coupling permits

fan is plugged in so that it runs, the current of air from

the oil to return to the pump as soon as it has delivered

the running fan will cause the blades of the other fan to

its energy to the turbine.

turn. In this case, the air takes the place of the fluid.

Since the two fans are not enclosed or closely coupled,

Where the vehicle has not started to move, the

this sort of coupling is not very efficient.

turbine is stationary. For instance, the engine may be

rotating the pump at 900 rpm. The pump is

To make a more efficient coupling, oil is used, and

consequently imparting energy to the fluid, which, in

the two members (driving member and driven

turn, imparts energy to the turbine. By the time the oil

member) are mounted very close together and

returns to the pump, the pump has moved some

enclosed in a housing. In a fluid coupling, the driving

distance, making it impossible for the oil to re-enter the

member is called the PUMP and the driven member the

pump through the same set of vanes it left. Consider

TURBINE. This terminology is not universal. Some

one drop of oil as it leaves the pump, goes through the

manufacturers call the pump the IMPELLER or

AIR IS COUPLING FLUID

TURBINE

PUMP

ASf02048

ASf02049

Figure 2-48.--Basic fluid coupling, using air in place

Figure 2-49.--Fluid coupling pump and turbine.

of fluid.

2-40