The foregoing discussion of torque converters is

general, and is adaptable to the operational

understanding of any hydraulic torque converter.

RADIATOR

TRANSMISSION

Actually, the changeover from stall speed to coupling

ENGINE

speed in the converter, as outlined above, is not sudden

but gradual and is determined by the power demands of

the load and/or operator. When the vehicle begins to

COOLER

move, there is one power demand. Then, as the turbine

speed begins to increase, the oil flow direction in the

converter begins to shift. The shifting oil pattern

ASf02054

effects the torque multiplication. This effectively

Figure 2-54.--Typical radiator-type oil cooler.

reflects changing power demands, and is similar to a

members on an overrunning clutch. In most cases,

gear-type transmission with an infinite number of gear

either an overrunning (one-way) clutch of the roller

ratios.

type or a sprag unit type is used.

The torque converter, like the fluid coupling, can

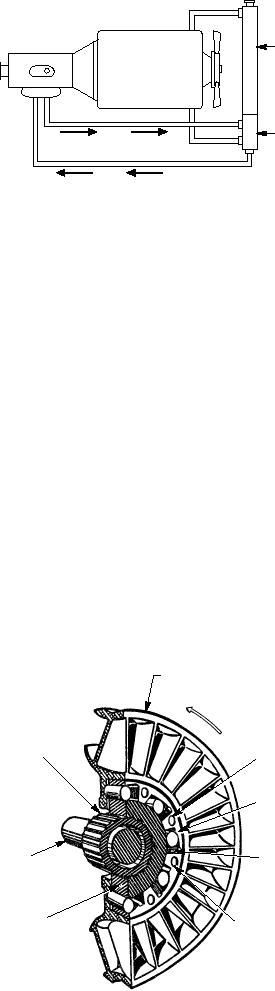

A typical roller-type overrunning clutch is shown

be used as a coupling between the engine and a

in figure 2-55. Notice the shape of the spaces

m e c h a n i c a l c l u t c h . H ow eve r, s i n c e t h e t o r q u e

surrounding the rollers in the clutch cam. When the

converter can effectively vary torque ratios, a

member overruns, the rollers move against light

transmission is not always required. There is no reverse

springs into the larger spacing in the cam, thus

or neutral on the torque converter; therefore, a

allowing freewheeling. If the member slows down, the

transmission is normally used to meet the demands

rollers are wedged into the smaller spaces by light

required of most moving vehicles. Some converters

springs and clutch hub rotation. This action locks the

also incorporate a lockup clutch and a retarding device

rotating member to the shaft.

within the converter hydraulic system.

A sprag unit assembly is shown in figure 2-56. This

Converter Hydraulic System

assembly consists of an inner and outer race, thrust

washers, snap ring, and the required number of sprag

The converter hydraulic (oil) system usually

units. The sprags (fig. 2-56, view A) are usually held in

consists of a reservoir, a supply pump, a filter, and a

alignment and on a slight angle between the inner and

cooler. When the converter is used in conjunction with

outer race by an energizing spring.

an automatic transmission, the sump of the

The operation of a sprag assembly can be seen in

transmission is used as the reservoir, since the oil is

detail in of figure 2-56, view B. As long as the inner or

circulated to the converter and other hydraulic units of

the transmission by the supply pump.

STATOR

The cooler, or heat exchanger, is used to dissipate

TORQUE CONVERTER

the heat that is generated by the converter. The oil is

ROTATION

constantly subjected to agitation and motion when the

OVERRUNNING

vehicle is operating, thus it becomes very hot. Some

CLUTCH HUB

SHAFT

OVERRUNNING

converters have fins on the pump housing similar to the

CLUTCH CAM

fins on an air-cooled engine to dissipate the heat.

OVERRUNNING

Others use the circulating coolant of the vehicle's

CLUTCH ROLLER

engine for cooling, while still others use a heat

exchanger of the radiator type. A typical radiator-type

TURBINE

SHAFT

OVERRUNNING

heat exchanger is shown in figure 2-54. This type of

CLUTCH SPRING

cooler is mounted with the radiator for the vehicle's

engine.

OVERRUNNING

CLUTCH HUB

OVERRUNNING

CLUTCH CAM

RIVET

Overrunning Clutch

For the torque converter to function properly, the

ASf02055

stator or stators and the secondary members must be

Figure 2-55.--Roller-type overrunning clutch.

able to overrun. This is made possible by mounting the

2-44