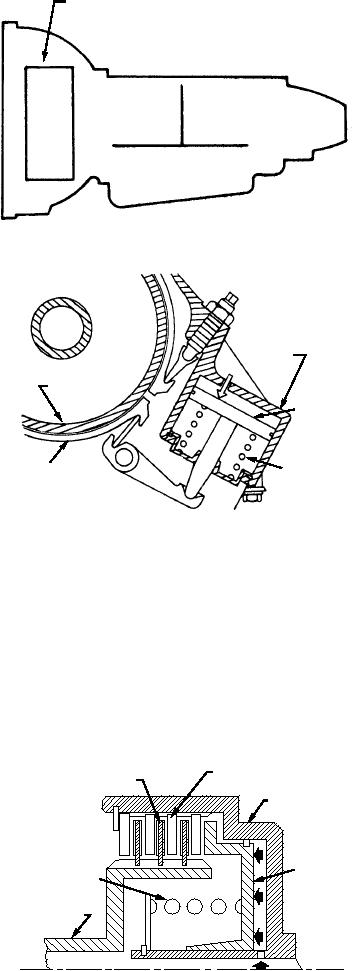

Complex Planetary Gear System

TORQUE CONVERTER

As in the case of simple machines, complex

planetary systems are merely combinations of two or

more of the simple planetary units. Planetary units can

be arranged to provide several different conditions or

HYDRAULIC

RANGE

gear ratios. However, only two of these conditions can

OPERATING

SECTION

be used for each unit--either direct drive and a gear

UNITS

reduction, or reverse and direct drive. This shows that a

HYDRAULIC

single planetary unit is actually a two-speed

CONTROL UNIT

transmission. All that is needed to operate the unit is a

ASf02062

way to hold any one member to provide a reduction in

speed (torque increase), and a way to lock any two

members together for direct drive. Of course, the single

Figure 2-62.--Representative transmission groups.

unit would not provide the tractive torque and variable

speeds necessary on some types of support equipment.

For this reason most automatic transmissions contain

two or more planetary units (complex planetary

system) arranged to provide the required tractive

CYLINDER

torque for starting and moving heavy loads, and also

(SERVO

providing variable forward speeds as well as a reverse

BODY)

DRUM OR

gear.

RETAINER

PISTON

There are inherent advantages to the planetary gear

system. For example, since each gear of the planetary

FRICTION

BAND

unit is in contact with at least two other gears of the

SPRING

unit, there is a lot of gear tooth contact to carry the load.

Another advantage is that the gears are always in mesh,

ASf02063

and there is no tooth damage due to tooth clash or

Figure 2-63.--Servo unit.

partial engagement. However, the big advantage, and

pressure applied to the piston into mechanical force,

the one that makes it so popular, is the ease of shifting

thus controlling the application of the brake (friction)

gears, which can be done automatically.

band. When the brake band is applied, a member of a

planetary gear unit is held stationary, providing a

CONSTRUCTION OF AN AUTOMATIC

specific gear ratio.

TRANSMISSION

The clutches, like the servo units, normally use

The components of an automatic transmission can

hydraulic pressure for their actuation and a return

be divided into four groups--the torque converter, the

spring for release. Clutches can be of various designs,

range or gearing section, the operating units, and the

but most are the multiple friction disc type (fig. 2-64).

hydraulic control units. These four groups are shown in

The clutch discs can be wet or dry--the major

figure 2-62. The torque converter and range or gear

CLUTCH PLATE

section incorporating the use of a planetary gear train

CLUTCH DISC

(two or more planetary units) were discussed earlier.

CLUTCH

Therefore, only the operating units and hydraulic

RETAINER

control units are discussed in depth in this section.

Operating Units

PISTON

RELEASE SPRING

SHAFT

The operating units of the transmission are the

AND DISC HUB

servos and clutches. The servo unit (fig. 2-63) consists

of the servo body (containing the cylinder, piston, and

return spring) and the friction band (attached to the

APPLY PRESSURE

body), which is used to stop or hold a rotating drum or

ASf02064

Figure 2-64.--Multiple disc clutch unit.

retainer. The servo simply converts the hydraulic

2-49