In some transmissions only one oil pump may be

used, and it is mounted at the front of the transmission.

However, most manufacturers of support equipment

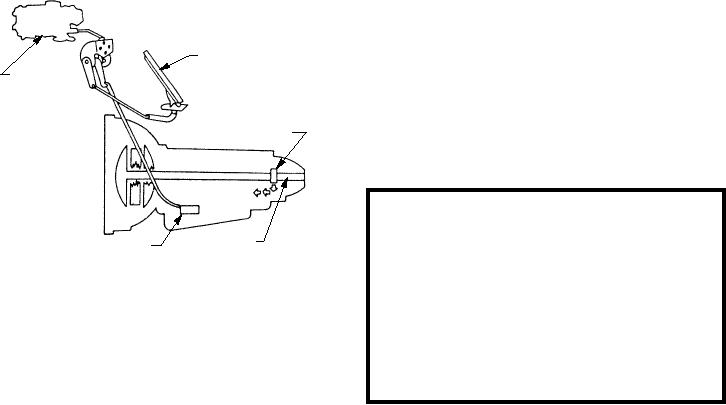

ACCELERATOR PEDAL

use a pump at both the front and rear of the

CARBURETOR

transmission. This allows the vehicle to be "push

s t a r t e d ," w h e r e a s w i t h t h e s i n g l e p u m p ,

"push-starting" cannot be accomplished, since the

GOVERNOR

engine must be operating to drive the torque converter

and the pump.

HYDRAULIC

CONTROL

WARNING

UNIT

OUTPUT

Pushing or pulling a vehicle equipped with an

SHAFT

THROTTLE VALVE

automatic transmission is extremely dangerous

ASf02066

and can result in damage to the equipment and

Figure 2-66.--Typical throttle valve and linkage.

injury or death to personnel. A vehicle equipped

with an automatic transmission should not be

Figure 2-66 shows a typical throttle valve and

pushed or pulled except in an extreme emergency,

linkage. The throttle valve delays the upshifting and

and then only after all possible precautions are

regulates oil pressure proportional to the accelerator

taken to eliminate the dangers involved.

pedal position or carburetor throttle opening. The

governor valve causes the upshifting and regulates oil

pressure proportional to the transmission output shaft

Pressure Regulator

speed.

The kickdown valve provides a means of forcing a

Oil from the pumps must be delivered to the

downshift to a lower gear ratio when it is desirable,

operating units under regulated pressure. To obtain this

such as when accelerating rapidly. The torque

regulated pressure, a pressure-regulating valve is

converter control valve controls the pressure and flow

incorporated into the system pressure line. Figure 2-67

of oil to the torque converter and to the lubricating

shows an oil pressure regulator. Oil from the pump or

passages of the transmission. Valves, metering

pumps flows to the chamber between two lands of a

orifices, or restrictions are added to the hydraulic

spool valve. Movement of the valve in one direction is

system to help time and smooth out the operations of

limited by a mechanical stop. Movement in the other

the transmission.

direction is limited by a spring calibrated to the

required system pressure (usually around 80 to 90 psi).

HYDRAULIC CONTROL SYSTEM

As shown in figure 2-67, oil flows from the

chamber of the regulator valve to the manual valve and

The h y d r a u l i c c o n t r o l s y s t e m m a k e s t h e

back to the rear of one large land in the regulator valve.

transmission fully automatic, and to do its job

This area of the regulator valve is known as the

completely, must consist of a fluid source, pressure

secondary reaction area. Also notice there is an oil flow

supply system, hydraulic operating units, and control

from the pumps to the rear of the small land of the

units for regulating both fluid flow and pressure.

secondary reaction area. This area is known as the

The fluid source is the fluid contained in the

primary reaction area. In looking at the two reaction

transmission oil pan, normally referred to as a sump.

areas, notice the working areas of the lands. There will

The fluid is strained through a filter as it flows from the

be no regulated pressure (at least not 80 to 90 psi) until

sump to the pump or pumps.

oil has reached the secondary reaction area of the

valve.

The hydraulic system must maintain the oil under

pressure for its various components to function

After the oil has entered the secondary reaction

properly. It is the job of the pump or pumps to remove

area, the force of the oil acts on both the large and small

oil from the sump and deliver it under pressure to the

lands in the area. When the pumps have supplied

systems. The pumps can be of several different

sufficient pressure, the resulting force acting on the

designs, however, most manufacturers use the internal

large land of the secondary reaction area moves the

valve to the left against the spring. This movement

gear, constant displacement pump.

2-51