WHEEL RIMS

This rim is used on rear axles of towing tractors and

similar heavy duty vehicles. Rims are mounted with

The three types of rims most commonly used on

the demountable flange outboard on single wheel

SE are the solid rims, split rims, and demountable

installations, and facing each other on dual wheel

flange rims.

installations.

Solid Rims

TIRES

Solid rims are made in one piece and are

The types of tires most commonly used on SE are

permanently fastened to the wheel hub (fig. 2-94).

bias ply, bias belted, radial, tubeless, and solid rubber

They feature a well in the center that permits mounting

tires.

and demounting of the tire. This type of rim is often

Bias Ply

referred to as a drop center rim, and is generally used

on smaller vehicles and light trucks.

In bias ply tires, tire cords are arranged in two or

more (even number) plies, depending on the strength

Split Rims

desired in the finished tire. The cords, or plies, cross

Split rims consist of two, usually identical, halves

the tire circumference at an angle, usually 30 to 40

secured together by tie bolts. They are usually mounted

degrees. This design provides rigidity in both sidewall

on handling equipment, small trailers, and front wheel

and tread. A disadvantage is that bias ply tires squirm

assemblies of towing tractors. When assembling split

more and tend to run hotter than belted bias or radial

rim wheels, you must ensure that steel and aluminum

tires.

halves are not mixed. Mixing different types of wheel

Bias Belted

halves may cause cracks and wheel failure.

Constructed similarly to bias ply tires, belted tires

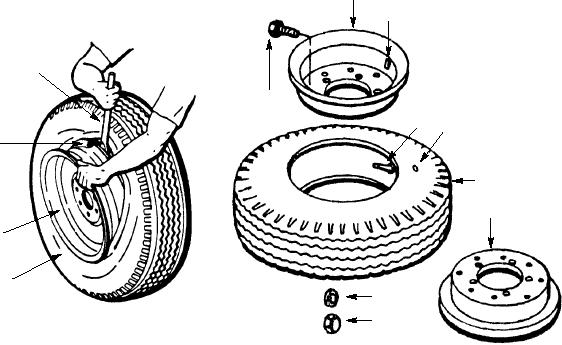

Demountable Flange Rims

will have an additional two or more layers of fabric

The demountable flange rim consists of two parts:

(belts) under the tread. The cords in the belt also run at

the rim base and the demountable flange. The

an angle, about 25 degrees to the circumference. This

demountable flange (split ring) holds the tire by

construction provides the sidewall stiffness of the bias

ply with increased strength and stiffness in the tread.

interlocking with the rim base when the tire is inflated.

1.

LOCKWASHER

3

2.

NUT

4

3.

OUTER RIM HALF

1. TIRE

4.

VALVE STEM HOLE

2. RIM

5.

VALVE STEM

3. FLANGE

6.

TIRE BALANCE MARK

1

7.

TIRE

8.

INNER RIM HALF

9

9.

TIE-BOLT

5

6

3

7

8

2

1

1

2

A. SOLID RIM

B. SPLIT RIM

ASf02094

Figure 2-94.--Solid and split rims.

2-79