The liners are inserted into a hole in the block with

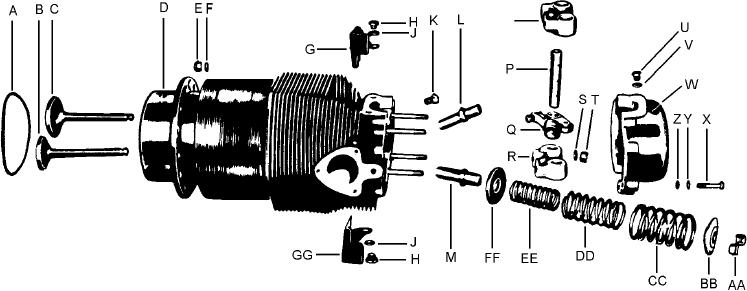

The air-cooled engine differs from the

either a press fit or a slip fit. Liners are further

liquid-cooled engine in that the cylinders have closely

designated as wet-type or dry-type. The wet-type liner

spaced fins surrounding the barrel. (See fig. 3-18.)

comes in direct contact with the coolant and is sealed at

These fins provide a greatly increased surface area from

the top by the use of a metallic sealing ring and at the

which heat can be dissipated. This is in contrast to the

bottom by a rubber sealing ring; the dry-type liner does

liquid-cooled engine, which has a water jacket around

not contact the coolant. Special precautions must be

its cylinders.

taken with the seals when installing a wet-type liner.

The cylinder block is cast from gray iron or iron

Use a lubricant on the seals to prevent them from rolling

alloyed with other metals such as nickel, chromium, or

or twisting. Soap or brake fluid is recommended for this

molybdenum. Some lightweight engine blocks are

purpose. Continued overheating of an engine during

made from aluminum alloy. Cylinders are machined by

operation or improperly installed seals will allow the

grinding or boring to give them the desired true inner

coolant to enter the crankcase and contaminate the

surface. During normal engine operation, cylinder

engine oil. To determine which seals are leaking, it is

walls will wear out-of-round, or they may become

necessary to remove the engine oil pan or inspection

cracked and scored if not properly lubricated or cooled.

covers on the crankcase and pressurize the cooling

Liners (fig. 3-19) made of metal alloys resistant to wear

system, observing the liners through the crankcase for

are used in many gasoline engines and practically all

leakage.

diesel engines to lessen wear. Liners for 4-stroke cycle

Cylinder wear is caused by dirt getting through the

engines do not have air inlet ports, as shown in figure

air cleaner and acting as a grinding compound, by side

3-20. After they have been worn beyond the maximum

thrust of the piston, and by pressure of the piston rings

oversize, the liners can be replaced individually,

against the cylinder walls. Liners, therefore, do not

permitting the use of standard pistons and rings. Thus,

completely prevent wear. To check on wear and to

you can avoid replacing the entire cylinder block.

determine how much overhaul is required, use special

N

ASf03018

Y. Lock washer

M.

Exhaust valve guide

A.

O-ring gasket

Z. Washer

N.

Rocker support bracket

B.

Exhaust valve

AA. Valve lock

P.

Rocker shaft

C.

Intake valve

BB. Valve spring retainer

Q.

Rocker

D.

Cylinder

CC. Outer valve spring

R.

Rocker support bracket

E.

Cylinder barrel nut

DD. Intermediate valve spring

S.

Washer

F.

Lock nut

EE. Inner valve spring

T.

Slotted nut

G.

Dome fin deflector (LH)

FF. Valve spring seat

U.

Rocker box cover plate bolt

H.

Bolt

GG. Dome fin deflector (RH)

V.

Tab washer

J.

Lock washer

W.

Valve rocker cover

K.

Primer nozzle assembly

X.

Bolt

L.

Intake valve guide

Figure 3-18.--Cylinder of an air-cooled engine.

3-16