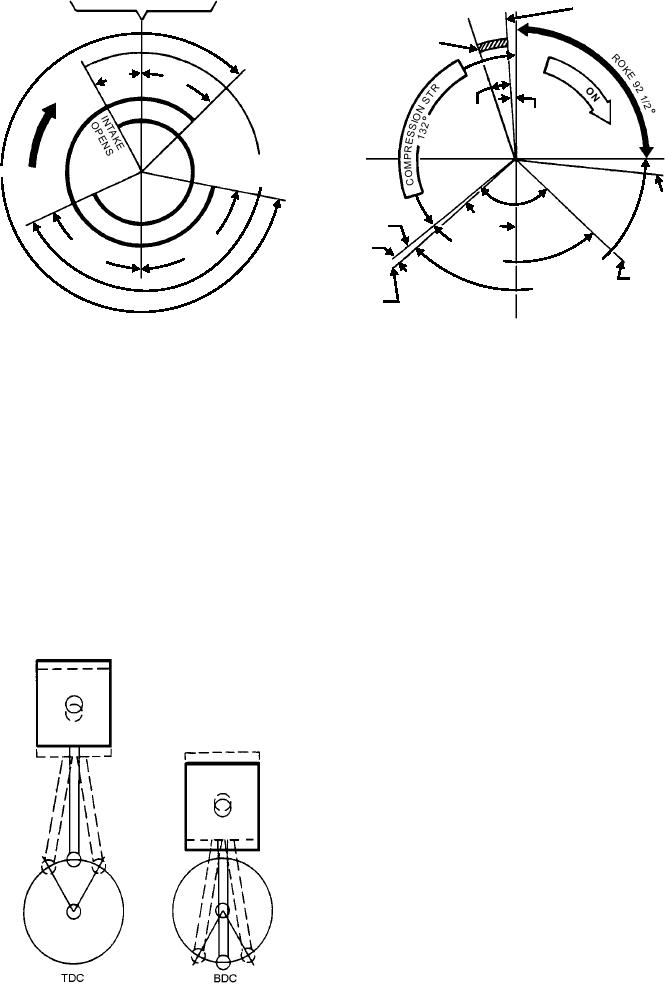

TOP DEAD CENTER

TDC

INJECTION ENDS

PO

WE

INJECTION

R

BEGINS

ST

28

45

RO

TA

KE

DEG

DEG

TI

O

ST

17 1/2o

o

5

AU ES

H S

EX LO

C

279 DEG

EXHA

E

UST

AK

303 DEG

INT SES

OPEN

S

O

o

CL

48 o 48

PISTON

COVERS

44

VALVE

1/2o

PORTS

CLOSES

71

G

96

o

DE

o

3 1/2

DE

INT

8

G

A

7

KE

ST

AU

PISTON

PISTON

o XH

132 E

COVERS

COVERS

PORTS

PORTS

BDC

2-STROKE VALVE TIMING DIAGRAM

4-STROKE VALVE TIMING DIAGRAM

ASf03014

Figure 3-14.--Typical valve timing diagrams.

At higher speeds, there is still less time for the

Ignition Timing

fuel-air mixture to ignite and burn. To compensate for

Ignition timing refers to the timing of the spark

this, and thereby avoid power loss, the ignition system

plug firing with relation to the piston position during

includes both a vacuum and a mechanical advance

the compression stroke. The ignition system is timed so

mechanism that alters ignition timing as engine speed

that the spark occurs before the piston reaches TDC on

increases.

the compression stroke. This gives the mixture enough

Q3-7. What is the major difference in the ignition

time to ignite and start burning. If this time were not

processes of a gasoline and diesel engine?

provided (that is, if the spark occurred at or after TDC),

1. A gasoline engine uses spark plugs to

then the pressure increases would take place too late to

ignite the fuel and a diesel engine heats

provide a full power stroke.

the air in the cylinder by compressing it to

ignite the fuel

2. A gasoline engine uses spark plugs and a

diesel engine uses an igniter coil to ignite

the fuel

3. A gasoline engine uses electronic ignition

and a diesel engine uses an igniter coil to

ignite the fuel

4. A gasoline engine works on the theory of

high compression with low ignition and

the diesel engine works on the theory of

high compression with high ignition

Q3-8. The rate at which work is done is identified by

which of the following terms?

1.

Energy

2.

Power

3.

Inertia

ASf03015

4.

Wattage

Figure 3-15.--Rock positions.

3-13