C h o k e Va l v e

Choke Circuit

When the engine is cold, the gasoline vapors tend to

condense into large drops on their way to the cylinders.

Spring

Because all the gasoline supplied to the cylinders will

not vaporize, it becomes necessary to supply a richer

mixture to have enough vapor to assure combustion.

This is accomplished by the choke circuit, which is a

choke valve plate placed in the carburetor throat above

the venturi.

ASf04019

When an operator sets the choke, the choke valve

tilts in the air horn to reduce the amount of air entering

Figure 4-19.--Off-center choke valve.

the throat, giving a very rich mixture. Only the volatile

parts of the gasoline will vaporize at cold temperatures;

overcomes the spring tension and opens the choke valve

therefore, a rich mixture is necessary. It provides

part way, admitting enough air to prevent overchoking

enough ignitable vapor to start the engine. However, if

or flooding the engine. As the engine warms up, the

the choke valve is in the full-choke position, it is

choke valve is gradually advanced to the wide-open

completely closed, shutting off the supply of air.

position by the operator to supply the leaner mixture

Consequently, there is not enough air entering the

required for a hot engine.

throat to allow the gasoline to ignite. The necessary air

In most modern engines, automatic chokes (figs.

is admitted in manual chokes by either one of two

4-20 and 4-21) have replaced the conventional manual

semiautomatic features.

choke. They control the fuel-air ratio for quick starting

In one design, the choke valve incorporates a

at low temperature and also provide for the proper

spring-loaded poppet valve (fig. 4-18). The poppet is

amount of choking to enrich the fuel-air mixture for all

held in the closed position by a weak spring. As soon as

conditions of engine operation during the warm-up

the engine turns over, there is sufficient pressure

period. The automatic choke built into the carburetor in

differential to open the valve, allowing a small amount

figure 4-20 consists of a thermostatic (bimetal) spring

of air to flow.

and a vacuum piston, which opposes the action of the

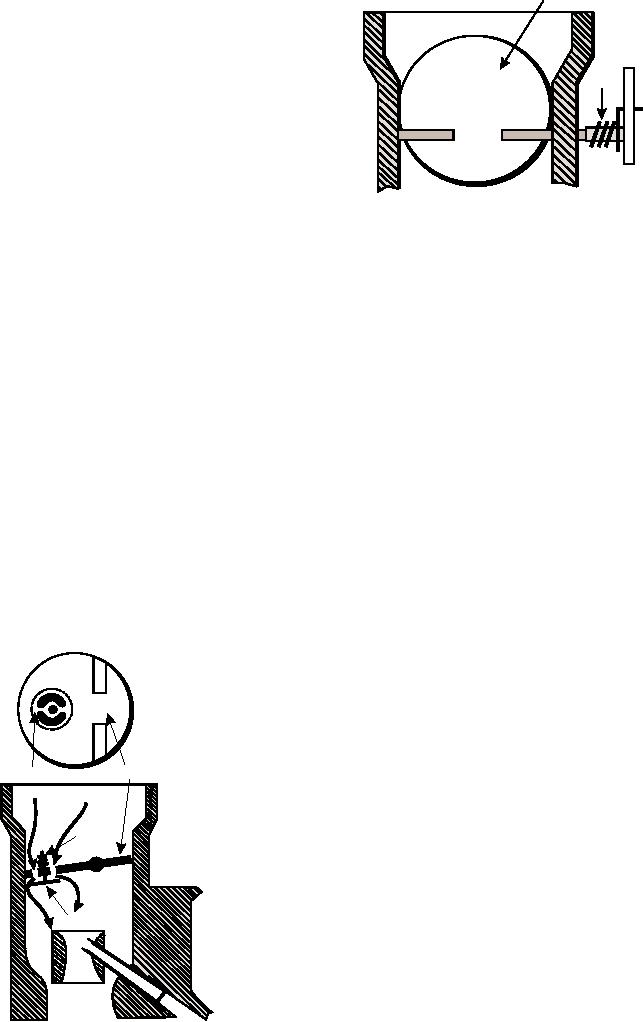

In the other design, the valve is off-center (fig.

spring. The spring is connected to the choke valve in

4-19) and operated through a coiled spring on the end of

such a manner as to close the valve when the spring is

the choke shaft. In the full-choke position, the spring

cold. The vacuum piston tends to open the choke valve

holds the choke valve in the closed position. As soon as

when the engine manifold vacuum is high. The choke

the engine turns over, an increased pressure differential

valve is mounted off-center on the choke shaft so that

any increase in air velocity through the air horn will

tend to open the valve.

The operation of the automatic choke, shown in

figure 4-20, is dependent on three factors: heat, intake

manifold vacuum, and the velocity of air passing

through the air horn. When the engine is cold, the

thermostatic spring holds the choke valve closed. When

Choke Valve

Poppet Valve

the engine is started, the low pressure (high vacuum)

Air

below the throttle valve permits atmospheric pressure

to move the piston down and partially open the valve

Spring

against the tension of the thermostatic spring. Under

varying load conditions during warm-up, the position

of the choke valve will be changed by the operation of

the vacuum piston working against the thermostatic

Poppet Valve

spring, and the air velocity in the air horn. Hot air from

the exhaust manifold is directed to the thermostatic

spring so that the spring loses its tension as the engine is

heated. This permits the choke to open gradually and,

after it reaches full-open position, it is held open by the

action of the intake manifold on the piston. When the

ASf04018

Figure 4-18.--Spring-loaded poppet valve in choke valve.

4-12