ASf08007

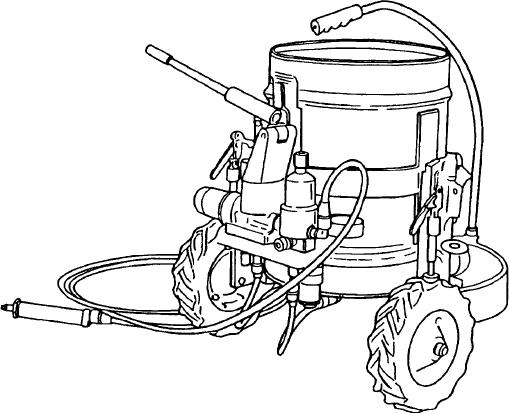

Figure 8-7.--Fluid Service Cart, Model 310.

A few of the most common types of rotary pumps

pump. When a fixed displacement pump is used in a

hydraulic system, a pressure regulator (or unloading

are discussed in the following paragraphs. All of the

valve) is used to control the amount of pressure in the

pumps discussed are gear pumps, so called because

system. The pressure regulator also unloads or relieves

they use gears to trap the fluid. This style of pump is

the pump when the desired pressure is reached. This is

ve r y s i m p l e i n d e s i g n a n d fi n d s w i d e u s e i n

to keep the pump from working against a load when the

low-pressure hydraulic systems. A gear pump delivers

hydraulic system is at maximum pressure and not

a constant volume of fluid at any given rpm.

functioning. During this condition, the pressure

SPUR TOOTH PUMPS.--The gear-type rotary

regulator bypasses the fluid from the pump back to the

pump shown in figure 8-8 is called a spur tooth pump. It

reservoir. The pump, all the while, continues to deliver

consists of two meshed gears that revolve alongside

a fixed volume of fluid during each cycle. In this type

each other in one housing. The driving gear is turned by

of system you also need a relief valve to bypass

a drive shaft, which engages the power source. The

pressure if the regulator or unloading valve fails.

clearances between the gear teeth and the pump

Rotary Pumps

housing are very small.

The inlet port is connected to the fluid supply line,

Rotary pumps operate by means of rotating parts

and the outlet port is connected to the pressure line. In

that trap the fluid at the inlet (suction) port and force

the pump shown in figure 8-8, the drive gear rotates

it through the discharge port into the hydraulic

c o u n t e r c l o c k w i s e a n d t h e d r ive n g e a r r o t a t e s

system. Gears, lobes, and vanes are commonly used

clockwise. As the teeth pass the inlet port, fluid is

as elements in rotary pumps. Rotary pumps are of the

fixed displacement type.

trapped between the teeth and the housing, and is

carried around the housing to the outlet port. As the

There are many types of rotary pumps that are

teeth mesh again, the liquid between the teeth is

classified in various ways. They may be classified by

displaced into the outlet port. This action produces a

shaft position (vertically or horizontally mounted); by

positive flow of liquid into the system. A shear pin or

the type of drive (electric motor, internal combustion

shear section is incorporated in the drive shaft to

engine, etc.); by manufacturer's name; or by service

protect the power source or reduction gears if the pump

application. However, rotary pumps are usually

classified by the types of rotating elements they use.

fails because of excessive load or binding of parts.

8-8