preventive maintenance inspections. Double-action

from the inlet chamber to the outlet chamber. Because

pumps are also used on support equipment, such as the

of the area occupied by the piston rod, the outlet

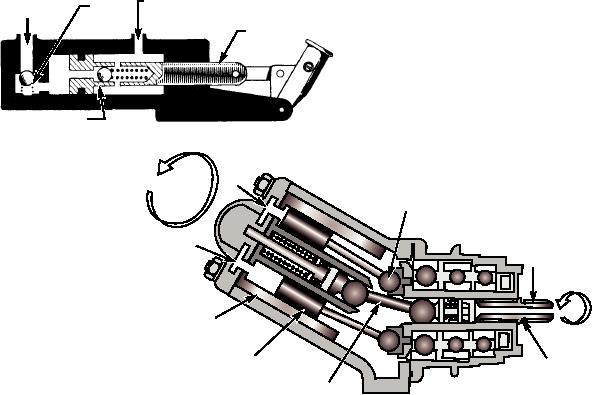

B-2 maintenance workstand. Figure 8-14 shows a

chamber cannot contain all the liquid discharged from

typical double-action hand pump.

the inlet chamber. Since the liquid will not compress,

the extra liquid is forced out of the outlet port into the

The double-action pump, shown in figure 8-14,

system, activating whatever device the pump is

consists of a cylinder, a piston with a built-in check

valve (A), a piston rod, an operating handle, and a

connected to.

check valve (B) at the inlet port. When the piston is

Maintenance of hand pumps includes frequent

moved to the left, spring tension and the force of the

pressure checks and inspections for leaks, general

liquid in the outlet chamber cause check valve A to

condition, and efficiency of operation. Operational

close. This movement causes the piston to force the

checks and removal and replacement procedures can

liquid in the outlet chamber through the outlet port and

be found in the applicable maintenance instruction

into the system. This same movement of the piston

manuals.

causes a low-pressure area in the inlet chamber.

Atmospheric pressure acting on the liquid in the

FIXED

D I S P L AC E M E N T

PISTON

reservoir transmits this pressure to the liquid at the

PUMPS.--Fixed displacement piston pumps are a

inlet port. The pressure differential acting on the ball of

type of axial piston pump. The fixed displacement

check valve B causes the spring to compress, opening

piston pump, shown in figure 8-15, produces a constant

the check valve. This allows liquid to enter the inlet

flow of fluid for any given rpm. The pistons, usually

chamber.

about nine, (always an odd number) are fastened by a

When the piston completes the stroke to the left,

universal linkage to a drive shaft. The universal link in

the inlet chamber is full of liquid. This liquid

the center drives the cylinder block, which is held at an

eliminates the low-pressure area in the inlet chamber,

angle to the drive shaft by the pump housing.

thereby allowing spring tension to close check valve B.

Everything within the pump housing rotates with the

When the piston is moved to the right, the force of

drive shaft. As the piston is rotated to the upper

the confined liquid in the inlet chamber acts on the ball

position, its movement forces fluid out of the pressure

of check valve A. This action compresses the spring

port. As the same piston moves from the upper position

and opens check valve A, allowing the liquid to flow

to the lower position, it draws in fluid through the

INLET

OUTLET

CHECK

intake port. Since each piston is always somewhere

PORT

PORT

VALVE

B

between the upper and lower positions, constant intake

PISTON

and output of fluid results. The volume output of the

pump is determined by the angle between the drive

shaft and the cylinder block, as the degree of angle

decreases or increases the piston stroke. The larger the

CHECK VALVE A

ASf08014

angle, the greater the output per revolution.

Figure 8-14.--Double-action hydraulic hand pump.

7

3

6

1

4

5

8

2

ASf08015

1. Drive shaft

3. Point of attachment

5. Piston

7. Pressure port

2. Universal link

4. Cylinder block

6. Intake port

8. Drive shaft seal

Figure 8-15.--Fixed displacement piston pump.

8-12