numbered. Note that the inner gear has one less tooth

As the rotor turns, centrifugal force keeps the

than the outer gear has spaces. The tooth form of each

vanes snug against the wall of the housing. The vanes

gear is related to that of the other in such a way that

divide the area between the rotor and housing into a

each tooth of the inner gear is always in sliding contact

series of chambers. The chambers vary in size

with the surface of the outer gear. Each tooth of the

according to their respective positions around the

inner gear meshes with the outer gear at just one point

shaft. The inlet port is located in that part of the pump

during each revolution. In view A of the figure, this

where the chambers are expanding in size so that the

point is indicated by an X. In view A, tooth 1 of the

partial vacuum (low-pressure area) formed by this

inner gear is in mesh with space 1 of the outer gear. As

expansion allows liquid to flow into the pump. The

the gears continue to rotate in clockwise direction and

liquid is trapped between the vanes and is carried to the

the teeth approach point X, tooth 6 of the inner gear

outlet side of the pump. The chambers contract in size

will mesh with space 7 of the outer gear, tooth 5 with

on the outlet side, and this action forces the liquid

space 6, etc. During this revolution, tooth 1 will mesh

through the outlet port and into the system.

with space 2; and in the following revolution, tooth 1

The pump is called unbalanced because all of the

will mesh with space 3. As a result, the outer gear

pumping action takes place on one side of the shaft and

rotates at just six-sevenths the speed of the inner gear.

rotor, causing a side load. Some vane pumps are

For example, if the inner gear rotates at 1,400 rpm, the

constructed with an elliptical-shaped housing. This

outer gear rotates at 1,200 rpm.

forms two separate pumping areas on opposite sides of

At one side of the point of mesh, pockets of

the rotor, canceling out the side load. Such vane pumps

increasing size are formed as the gears rotate; while on

are called balanced. Vane pumps are used extensively

the other side, the pockets decrease in size. The pockets

in power steering units in support equipment.

on the right-hand side of the drawings increase in size

as you move down the illustration, while those on the

Reciprocating Pumps

left-hand side decrease in size. The motion of the gears

draws fluid in on one side of the pump and pushes it out

The reciprocating pump, in one form or another, is

of the other side.

perhaps the most common type of hydraulic pump

found in support equipment. This type of pump

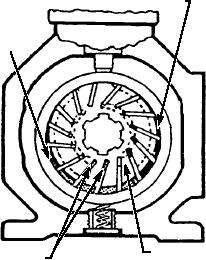

VANE PUMPS.--Figure 8-12 shows a vane pump

depends upon the reciprocating (back-and-forth)

of the unbalanced design. The rotor is attached to the

motion of a piston inside a cylinder. The hand pump

drive shaft and is rotated by an outside power source,

and the master brake cylinder are examples of

such as an electric motor or gasoline engine. The rotor

reciprocating hydraulic pumps. There are also several

is slotted, and each slot is fitted with a rectangular

types of power-driven reciprocating pumps, driven by

vane. These vanes, to some extent, are free to move

a variety of motors.

outward in their respective slots. The rotor and vanes

are enclosed in a housing, the inner surface of which is

Reciprocating pumps are most often used for

offset with the drive axis.

applications requiring high pressure and accurate

control of the discharge volume. There are many

variations of this type of pump, which in support

DISCHARGE

equipment is normally called a piston pump. Most of

the variations, however, are based on the axial piston or

INTAKE

hand pump principle. We will look at just a few in this

chapter. (There are also radial piston pumps, but they

are seldom used in support equipment.)

HAND PUMPS.--On most hydraulic systems, a

hand pump is only a substitute for the support

equipment's main power pump in case the power fails.

However, in some support equipment, a hand pump is

the only power source.

There are two major types of hand pumps--the

single-action and the double-action. In a single-action

SLIDING

ROTATING

VANES

ASf08012

ELEMENT

pump, the fluid is drawn into the cylinder on the first

Figure 8-12.--Vane pump.

(suction) stroke and forced out of the cylinder on the

8-10