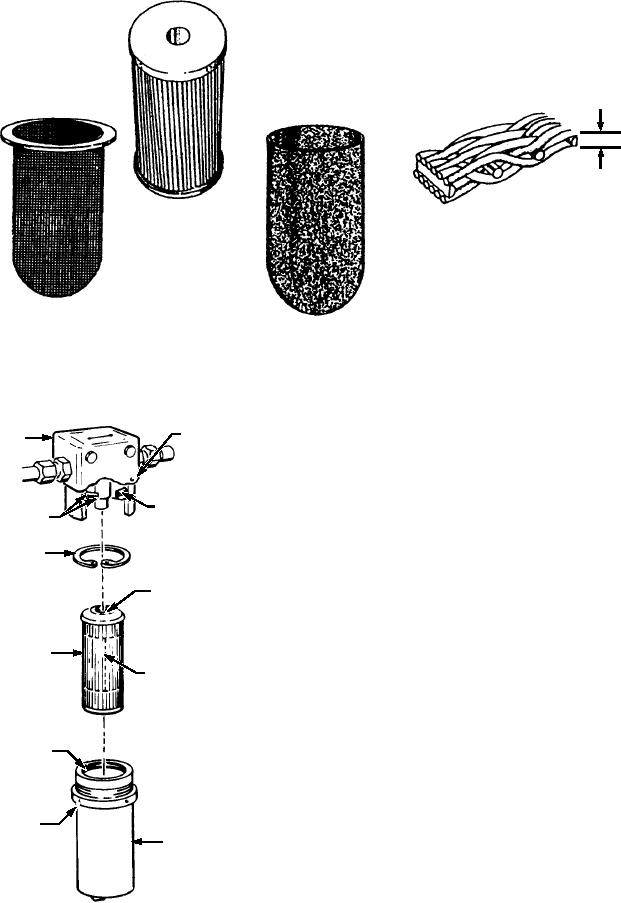

.0055 IN.

MICRONIC

CROSS-SECTION OF

FILTER

A STAINLESS STEEL

ELEMENT

HYDRAULIC FILTER

B

ELEMENT

D

WIRE

SINTERED

MESH

BRONZE

A

ASf08018

C

Figure 8-18.--Different types of hydraulic filter elements.

Some filter heads contain a differential pressure

LOCKWIRE

HEAD

indicator, which gives a visual indication of when the

HOLE

element should be changed. The bowl or filter case is

the housing that holds the element to the filter head,

BACKUP

O-RING

and it is removed when the filter element requires

RINGS

replacement.

RETAINING

RING

Filter Elements

O-RING

The size of particulate matter in hydraulic fluid is

(INSTALLED

IN ELEMENT)

measured in microns, (millionths of a meter). A micron

is equivalent to 0.0000394 inch, and 25,400 microns

ELEMENT

equal 1 inch. The largest dimension of the particle is

TO CHECK FOR

HYDRAULIC,

measured when determining its size. For comparison

SYSTEM CON-

value, consider that the normal lower level of visibility

TAMINATION,

CUT AS INDI-

RETAINING

to the naked eye is about 40 microns. (A grain of table

CATED BY

RING

DOTTED LINES

salt measures about 100 microns; the thickness of a

GROOVE

AND INSPECT

INTERIOR OF

human hair is about 70 microns; and a grain of talcum

ELEMENT.

powder is about 10 microns.) A graphic representation

LOCKWIRE

of the relative size of particles measured in microns is

HOLE

shown in figure 8-20.

BOWL

OR

MICRONIC-TYPE FILTER ELEMENTS.--

CASE

Micronic, a term derived from the word micron, can be

ASf08019

used to describe any filter element. Through usage,

Figure 8-19.--T-type micronic filter assembly.

micronic has become associated with a specific filter

with a filtering element made of a specially treated

The bypass filter assembly is used in this type system.

cellulose paper. The paper is formed in vertical

In aircraft hydraulic servicing equipment, the

convolutions (wrinkles) and is made in a cylindrical

non-bypass filter assembly is used because you would

pattern. A spring in the hollow core of the element

not want to service an aircraft system with

holds the element in shape (view B of fig. 8-18).

contaminated fluid.

8-15