indicator is to warn the operator that the filter element

and downstream of the primary element. The second

is clogged. The equipment can then be stopped before

stage filters out any media material released by the

the bypass valve opens, thus preventing contaminated

primary element and protects the system in the event

fluid from being passed through the hydraulic system.

the primary element should fail due to excessive

differential pressure. The secondary element also

Support Equipment Hydraulic Servicing

protects the system from contamination while the

Equipment Filters

primary element is being replaced.

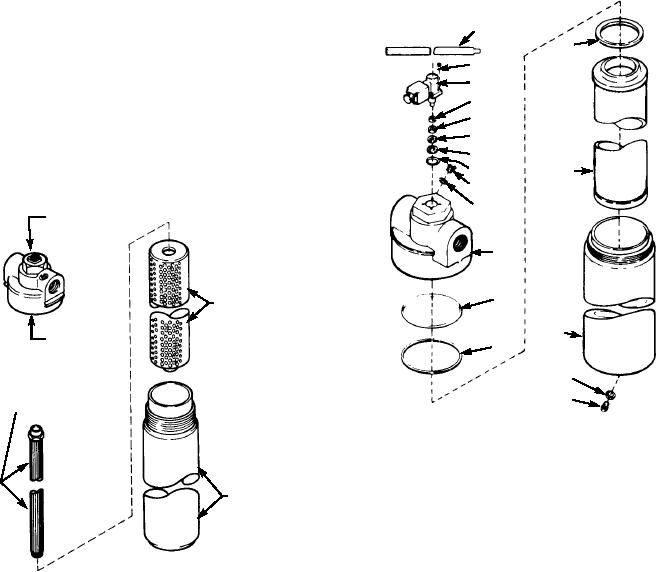

Other support equipment filters use only a single

To ensure delivery of contaminant-free hydraulic

stage, which consists of one large non-cleanable filter

fluid, all aircraft hydraulic servicing and test

cartridge (fig. 8-25). This configuration has been made

equipment use 3-micron (absolute) non-bypass

possible by improvements in filter elements that permit

filtration in their fluid discharge or output pressure

manufacture of a non-cleanable element capable of

lines. With many test stands, the filter used for this

withstanding 5,000 psi differential pressures and

application, in addition to having a low micron rating,

displaying negligible shedding of media material.

must be capable of withstanding high collapse

Filtration efficiency and dirt-holding capacity of the

pressures and hold large amounts of dirt. Filter

single-stage filter is comparable to that of the

assemblies and elements designed specifically for this

two-stage design, and it has the advantage of not

type of service are available from major filter

requiring second-stage element cleaning.

manufacturers and are presently being used in support

Non-cleanable, single-stage elements can be used to

equipment.

replace both the primary and secondary elements in

Several different types of 3-micron (absolute)

m o s t t wo - s t a g e fi l t e r a s s e m b l i e s . A p p l i c a b l e

high-pressure filters are commonly used in support

e q u i p m e n t . E a r l y m o d e l s ( fi g . 8 - 2 4 ) o f fi l t e r

assemblies used a two-stage design in which the

18

1

assembly contained both a large non-cleanable

17

primary filter cartridge and a cleanable metallic

16

s e c o n d a r y e l e m e n t . Wi t h t h i s d e s i g n , t h e

15

non-cleanable primary element provides the required

14

3-micron filtration and retains within its filter medium

13

virtually all particulate matter removed from the fluid.

12

The cleanable secondary element has a rating of 15

11

2

microns (absolute), and is physically located inside

10

9

DIFFERENTIAL

PRESSURE SWITCH

8

7

PRIMARY

FILTER

ELEMENT

3

HEAD

6

4

SECONDARY

FILTER

5

ELEMENT

ASf08025

1. Boss seal

10. Fill plug

2. Filter element

11. Preformed packing

3. Filter bowl

12. Backup ring

4. Preformed packing 13. Preformed packing

5. Drain plug

14. Sea ring

BOWL

6. Backup ring

15. Preformed packing

7. Preformed packing 16. Differential pressure switch

8. Filter head

17. Socket head cap screw

9. Preformed packing 18. Identification plate

ASf08024

Figure 8-25.--Typical high-pressure support equipment filter

Figure 8-24.--High-pressure filter.

assembly.

8-20