6

6

5

4

5

4

3

3

7

7

2

8

2

8

1

9

9

1

10

10

11

11

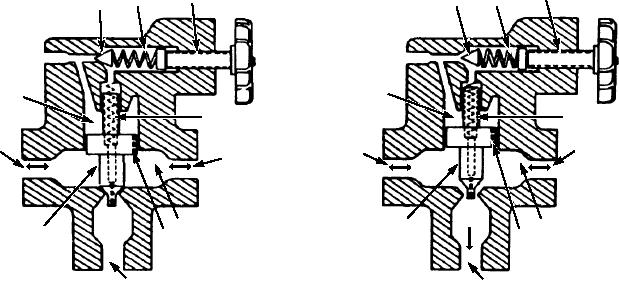

ASf08028

A

B

1. Piston

4. Pilot valve

7. Spring

10. Pressure port

2. Pressure port

5. Spring

8. Pressure port (inlet or outlet)

11. Return to reservoir

3. Fluid chamber

6. Adjusting screw

9. Fluid chanber

Figure 8-28.--Pilot-operated relief valve.

in both chambers 3 and 9. The tension of spring 7 then

Spring 7 will hold the piston (1) closed as long as

closes the piston (1).

the pressure in the chambers (3 and 9) remain equal.

The piston, in this condition, is referred to as being in

Relief valves of this type are used in some

hydraulic balance.

hydraulic test stands.

When an excessive pressure surge occurs, the

PRESSURE REGULATOR VALVES.--As the

pressure in chamber 3 stays basically unchanged

name implies, regulator valves are designed to regulate

because of the restriction of fluid flow of the fluid

system pressure between maximum and minimum

passage (10). The pressure surge in chamber 9

levels. These valves are often called unloading valves.

overcomes the combined pressure of chamber 3 and

They are designed to remove the system load from the

spring 7, and opens the piston (1) momentarily,

pump once the desired system pressure has been

decreasing the surge pressure by allowing fluid to flow

reached.

from chamber 9 to the return (11).

The functions performed by a regulator valve are

In a gradual pressure increase, the pressure in the

accomplished by its two operational phases--cut-in

chambers (3 and 9) remains balanced. When the

and cutout. A regulator is said to be cut-in when it is

pressure in chamber 3 equals the tension of the spring

directing fluid under pressure into a system. A

(5), the pilot valve (4) opens, thus decreasing the

regulator is cutout when it is bypassing fluid into the

pressure in chamber 3 by relieving the pressure

return line and back to the reservoir. Figure 8-29, view

through the centrally drilled passage in the piston (1).

A, shows a typical pressure regulator in the cut-in state.

The pressure in chamber 9 then exceeds the combined

In view A of figure 8-29, you can see that the pump

pressure of chamber 3 and spring 7, and thus opens the

supplies pressure to the top and bottom of the regulator

piston (1).

valve. At the top, the pressure acts on the 1/4 square

In actual operation, the piston (1) will open just

inch of the ball. On the bottom, the pressure acts on the

enough to allow excess fluid to escape. It will remain in

1 square inch of the piston. This creates a force

the open or throttled position as long as the resistance

differential between the two.

to fluid flow (causing pressure buildup) is present in

Pressure on the piston tries to lift the ball off of its

the system.

seat, but the force generated by the spring (600 lb) and

When system pressure decreases to the preset

the additional pressure exerted on the ball by the fluid

setting of the pilot valve, the tension of the spring (5)

in the upper part of the valve works to keep the ball

forces the pilot valve (4) on its seat. Because of the

seated. As long as the force differential between the

ball and the piston is less than the 600 pounds of the

passage (10) in the piston (1), fluid pressure equalizes

8-23