the actuating unit and serve alternately as pressure and

In view B, the spool is moved to the right of the

return lines. There are two main types of four-way

neutral position. In this position, one working line

control valves--the closed-center and the open-center.

(C1) is open to pressure, and the other working line

(C2) is open, through the hollow spool, to return. View

Figure 8-33 shows the operation of the valve. View

C shows the flow of fluid with the spool moved to the

A shows the valve in the neutral position. In this

left of neutral.

position, there is no flow through the valve, as the two

working ports (C1 and C2) are blocked off from the

T h e s e c o n t r o l va l ve s m a y b e d e s i g n e d a s

pressure and return ports.

individual units. However, in some systems, such as

the hydraulic systems of weapon loaders and some

View B shows the valve with the spool moved to

forklifts, two, three, or four control valves are

the left of the neutral position. In this position, one

combined into one controlling unit.

working port (C1) is open to pressure, and the other

working port (C2) is open to return. This allows the

Most directional control valves used in support

fluid to move in one direction.

equipment are operated manually, either directly or

In view C of figure 8-33, the spool is moved in the

through mechanical linkage. In some systems, these

opposite direction, to the right of the neutral position,

valves are operated electrically by solenoids.

the working port (C2) is open to pressure, and the

This is accomplished through the use of one or

working port (C1) is open to return.

more solenoids. A solenoid is a hollow, tubular-shaped

OPEN-CENTER DIRECTIONAL CONTROL

electric coil, made up of many turns of fine insulated

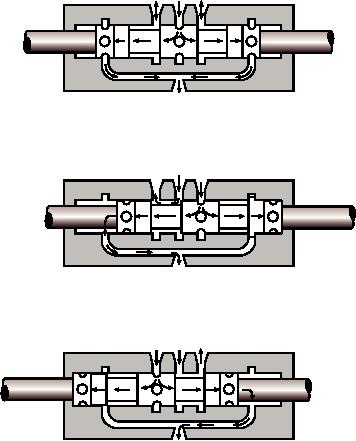

VALVE.--Figure 8-34 shows the operation of a

wire and possessing the same properties as an

typical open-center control valve. When this type of

electromagnet. The hollow coil imparts linear motion

valve is in the neutral position, as shown in view A,

to a movable core (or plunger) placed within the hollow

fluid flows into the valve through the pressure port

coil of the solenoid.

(P), through the hollow spool, and to the return.

To electrically operate the four-way valves shown

in figures 8-33 and 8-34, a solenoid is connected to

C1

P C2

each end of the valve. When the hollow coil of one

solenoid is energized, the plunger of the solenoid

moves and positions the sliding spool accordingly. By

energizing the solenoid on the opposite end, the sliding

spool moves in the opposite direction. Springs are

usually provided to move, and hold, the sliding spool to

TO RESERVOIR

the neutral position when neither solenoid is

A

energized. The solenoids are electrically connected to

switches that may be secured in a convenient location

C1

P

C2

for the operator. Solenoids are also used to operate

two- and three-way valves.

NOTE: In some subsystems, only one working

line is required from the control valve to the actuator. In

such systems, three-way valves are used. A three-way

TO RESERVOIR

valve contains three ports--a pressure port, a return

B

port, and one working port. Otherwise, three-way

valves operate much the same as four-way valves.

C1

P

C2

ACCUMULATORS

The purpose of an accumulator in a hydraulic

system is to store fluid under pressure. The following

are several reasons why it is useful to do this:

TO RESERVOIR

C

ASf08034

An accumulator can act as a cushion against

Figure 8-34.--Open-center directional control valve.

pressure surges in the system.

8-27