PRESSURE

Check valves are probably the most widely used

IN

RETURN

valves in fluid power systems. Check valves are also

used as integral parts of some more complex valves,

VALVE

SPOOL

such as sequence valves and counterbalance valves.

They are also used in pressure regulator valves, such as

the one pictured in figure 8-29. A variation of the check

valve--the orifice check valve--allows free flow in

one direction and a limited or restricted flow in the

opposite direction. (See figure 8-26.)

Check valves come in various designs. As shown

LEFT

RIGHT

PORT

PORT

earlier, balls, cones, and sleeves are commonly used as

A. LEFT POSITION

valve elements. Poppets, pistons, spools, and discs are

also used as valve elements in some types of check

valves.

PRESSURE

IN

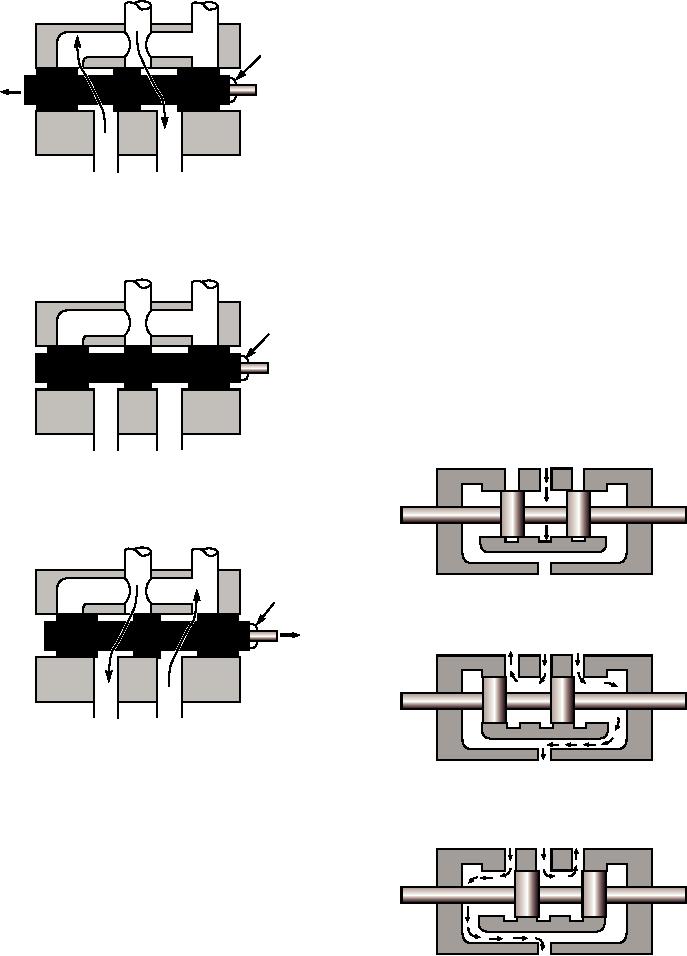

CLOSED-CENTER DIRECTIONAL CON-

RETURN

TROL VALVES.--The closed-center directional

VALVE

control valve shown in figure 8-33 is a four-way

SPOOL

control valve that is widely used in support equipment.

It has four ports--a pressure port, a return port, and two

working ports. The pressure port is connected to the

main pressure line, and the return port is connected to

the reservoir. The two working lines are connected to

C1 PRESSURE C2

LEFT

RIGHT

PORT

PORT

B. NEUTRAL

PRESSURE

IN

RETURN

RETURN

VALVE

SPOOL

A

C1 PRESSURE C2

LEFT

RIGHT

PORT

PORT

C. RIGHT POSITION

ASf08032

RETURN

Figure 8-32.--Spool directional valve.

B

CHECK VALVES.--A check valve is normally

C1 PRESSURE C2

classified as a one-way directional control valve

(although some manuals might identify them as flow

control valves). However, check valves permit flow in

one direction and prevent flow in the other. The force

of the fluid in motion opens a check valve, and it is

closed by fluid attempting to flow in the opposite

RETURN

direction, aided by the action of a spring or by gravity.

C

ASf08033

You could say that check valves are the "diodes" of the

Figure 8-33.--Closed-center directional control valve.

hydro-pneumatic world.

8-26