PRESSURE

IN

RIGHT

LEFT

PORT

PORT

OUTLET

RETURN

A.

NEUTRAL

INLET

PRESSURE

IN

A.

CLOSED

SLEEVE

LEFT

RIGHT

PORT

PORT

RETURN

B.

OUTLET

FORWARD

PRESSURE

IN

INLET

RIGHT

LEFT

PORT

PORT

B.

OPEN

ASf08030

Figure 8-30.--Operation of a simple poppet valve.

RETURN

C.

of the poppet to prevent leaks past this portion of the

REVERSE

housing. In most valves, the poppet is held in the seated

ASf08031

position by a spring. Some more complex valves may

Figure 8-31.--Operation of a rotary spool valve.

have multiple poppets.

of a spool and because the valve element slides back

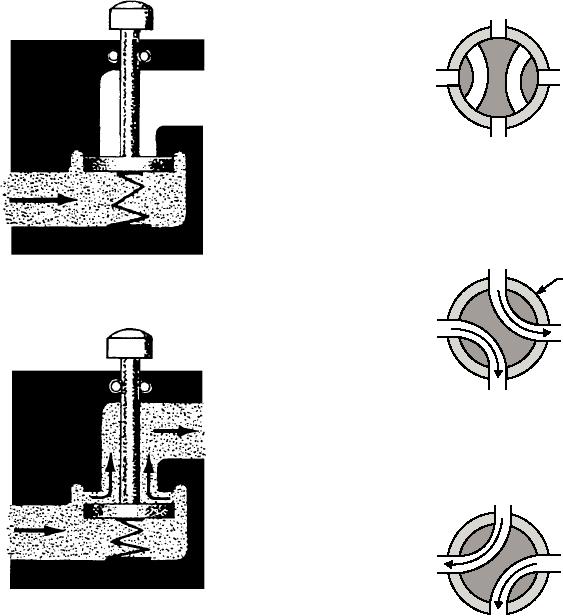

ROTARY SPOOLS.--A rotary spool directional

and forth to block and uncover ports in the housing.

control valve has a round core with one or more

In view B of the figure, the valve is shown in the

passages or recesses in it. (See figure 8-31.) The core is

neutral position (no fluid flow). By moving the spool

mounted within a stationary sleeve. As the core is

valve to the left position (as in view A), fluid flows

rotated within the stationary sleeve (generally by a

from the pressure line out through the right port, and

hand lever or knob), the passages or recesses connect

returns back through the left port to the return line.

or block the ports in the sleeve. The ports in the sleeve

Moving the spool to the right position (as in view C)

are connected to the appropriate pressure, working,

has a similar result; the left port becomes the pressure

and return lines of the fluid power system.

port, and the right port becomes the return port.

SLIDING SPOOLS.--A sliding spool is

Like all classes of directional control valves,

probably the most common type of valve element used

various methods are used for positioning the sliding

in directional control valves. Operation of the valve is

spool valve. Some of the more common methods are

illustrated in figure 8-32. The valve is so named

hand levers, cam angle plates, directional control arms,

and self-regulating poppet valve linkages.

because the shape of the valve element resembles that

8-25