RETURN

RETURN

UT TO 800 PSI

1/4 SQ.

1/4 SQ.

IN. BALL

IN. BALL

SPRING

SPRING

TENSION

TENSION

600 LBS.

600 LBS.

1 SQ. IN. PIST0N

1 SQ. IN. PISTON

MORE THAN 800 PSI

TRAPPED

UP TO 800 PSI

CHECK VALVE

CHECK VALVE

TO

TO

SYSTEM

SYSTEM

FROM PUMP

FROM PUMP

A

B

ASf08029

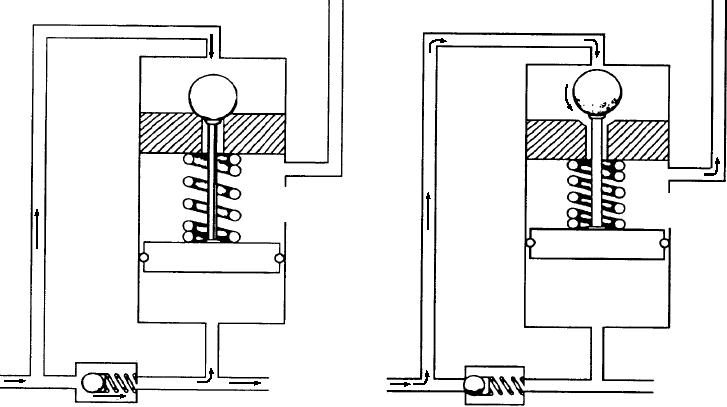

Figure 8-29.--Pressure regulator in the cut-in state (view A); and the cut-out state (view B).

element, which is the most common method. A

spring tension, the ball will remain seated. However, as

directional control valve can be one-way, two-way,

soon as that differential exceeds 600 pounds, the piston

three-way, or four-way.

will overcome the spring and lift the ball off of its seat,

as in view B of the figure.

The valve element of a directional valve may be

any one of three types:

When the ball is unseated, pressure in the top of the

valve drops immediately. At this point, the importance

A poppet--in which a piston or ball moves on

of the check valve can be seen. With the sudden

and off of a seat.

reduction in pressure, the check valve snaps shut, and

A rotary spool--in which the spool rotates about

fluid trapped in the system line continues to hold the

regulator piston in the raised position. This trapped

its axis.

fluid also maintains pressure on the system until the

A sliding spool--in which the spool slides

mechanism actuates or it is relieved by internal or

axially in a bore.

external leaking, either of which will cause the

regulator to cut back in.

Directional valves may be actuated mechanically,

manually, electrically, hydraulically, or pneumatically.

Hydraulic systems that use fixed displacement

pumps require pressure regulator valves. Those using

POPPETS.--Figure 8-30 illustrates the operation

variable displacement pumps do not.

of a simple poppet valve. The valve consists of a

movable poppet that closes against a valve seat. In the

Directional Valves

closed position, fluid pressure on the inlet side tends to

hold the valve tightly closed. Force applied to the top of

The purpose of a directional valve (also known as a

the poppet stem opens the poppet and allows fluid to

selector valve, transfer valve, or control valve) is to

flow through the valve.

control the direction of fluid flow, which, in turn,

controls the operation or direction of a mechanism.

The poppet, usually made of steel, fits into the

Such valves are classified in several ways, such as by

center bore of the seat. The seating surfaces of the

the number of ports in the valve housing, by the type of

poppet and the seat are lapped or closely machined so

control, and by the specific function of the valve.

that the center bore will be sealed when the poppet is

Another type of classification is by the type of valving

seated. An O-ring seal is usually installed on the stem

8-24