To see how it works, you need to apply some

in the fluid power systems of support equipment are the

pressure to the double-acting cylinder shown in figure

direct reading type. That is, the gauge is connected

8-37, view B. The stroke of the piston and piston rod

directly into the unit or lines leading to the unit and

assembly in either direction is produced by fluid

becomes part of the container or system. The gauge is

pressure. Assume that the cross-sectional area of the

able to sample the existing pressure at its location in the

piston is 3 square inches and the cross-sectional area of

system.

the rod is 1 square inch. In a 2,000-psi system, pressure

acting against the blank side of the piston creates a

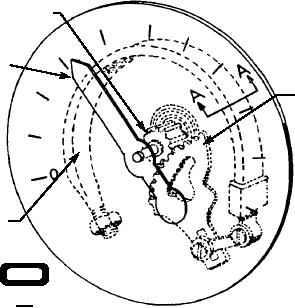

The Bourdon Tube

force of 6,000 pounds (2,000 psi 3 in.2). When the

The main part of a pressure gauge is the Bourdon

pressure is applied to the rod side of the piston, the

tube (fig. 8-38). It is a curved metal tube that is oval in

2,000 psi acts on 2 square inches (the cross-sectional

cross-sectional shape. One end of the tube is closed;

area of the piston less the cross-sectional area of the

the other end has a fitting for connecting it to a pressure

rod) and creates a force of 4,000 pounds (2,000 psi 2

in.2). As noted earlier, double-acting cylinders are

source. The fitting end is fastened to the frame of the

2

normally used in such a way that the blank side of the

gauge frame, while the other end is free to move so it

piston carries the greater load. That is, the cylinder

can operate the mechanical linkage.

carries the greater load during the piston rod extension

Assume that fluid pressure enters the Bourdon

stroke, which may be required to lift a heavy load, but

tube. Since fluid pressure will be transmitted equally in

when the piston rod is retracted, gravity helps make up

all directions and the area on the outside radius of the

loss of force caused by a smaller surface area. This

tube is greater than that of its inside, the force will also

same cylinder can be used to operate the side shift on a

be greater on the outside radius, which tends to

forklift where the working load is not as important as

straighten out the tube. As the movable end of the tube

the ability to move the load from side to side.

tries to turn outward, it turns the pivot segment gear.

A four-way directional control valve is normally

This gear meshes with a smaller rotary gear to which a

used to control the operation of this type of cylinder.

pointer is attached, and its movement causes a reading

The valve can be positioned to direct fluid under

on the pressure gauge. The gauge dial is calibrated so

pressure to either end of the cylinder, and to allow the

the needle points to a number that corresponds to the

displaced fluid to flow from the opposite end of the

exact pressure that is applied. When the pressure is

cylinder through the control valve to return the

removed, the Bourdon tube acts as a spring and returns

hydraulic fluid to the reservoir.

to its normal position.

Pressure gauges are designed to indicate different

PRESSURE GAUGES

ranges of pressure in pounds per square inch. In

support equipment, these gauges may range from 0 to

Pressure gauges installed in hydraulic systems are

used to indicate existing pressures. Most gauges used

100 psi, or up to 6,000 psi or greater. Figure 8-39 shows

ROTARY

GEAR

POINTER

PIVOT

SEGMENT

GEAR

BOURDON

TUBE

ASf08038

SECTION

A

A

Figure 8-38.--Bourdon tube.

8-31