FLOWMETER

HIGH

PRESSURE

COMPOUND

GAUGE

GAUGE

SELECTOR

ASf08039

VALVE

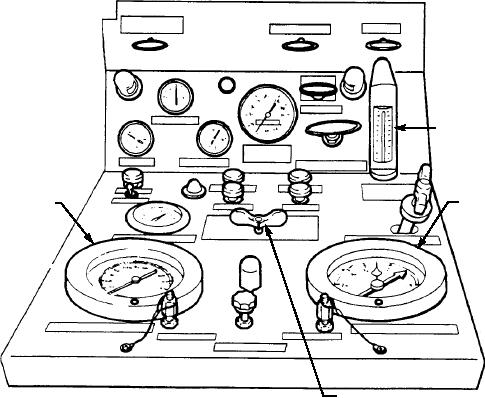

Figure 8-39.--A/M27T-5 control panel, controls, instruments, and gauges.

Pressure Gauge Snubbers

the control panel of the A/M27T-5 hydraulic test stand.

Note that the panel shows a variety of gauges. The large

A pressure gauge snubber (fig. 8-40) is a hydraulic

gauge on the left of the panel (1) is an example of a 0 to

component that is located upstream of a pressure

6,000 psi hydraulic pressure gauge.

gauge. Its function is to dampen out system pressure

surges that could cause damage to a gauge. Without a

Compound Gauges

snubber, pressure oscillations and sudden pressure

Compound gauges in hydraulic systems are used

changes could affect the delicate internal mechanism

to indicate pressure or suction in the system. They

of a gauge. Also, by removing oscillations, it makes a

normally indicate vacuum from 0 to 30 inches of

gauge easier to read.

mercury (in.Hg) and pressure from 0 to 300 psi. The

The basic components of a snubber are the

compound gauge shown in figure 8-39 (2) is used in

housing, fitting assembly (with a fixed orifice), and the

conjunction with the directional valves (3) to indicate

pin and plunger assembly. The snubbing action is

back pressure or suction in the return line, the inlet to

obtained by metering fluid through the snubber. The

the low-pressure pump, or the inlet to the high-pressure

fitting assembly orifice restricts the amount of fluid

pump.

that flows to the gauge, thereby snubbing the force of a

Defective gauges are removed and replaced with

pressure surge. The pin is pushed and pulled through

good ones. Defective gauges are then turned in to the

the orifice of the fitting assembly by the plunger,

AIMD calibration lab for repair or to be condemned

keeping it clear and at uniform size.

and deleted from the calibration inventory.

Calibration of Gauges

Flowmeters

If a pressure gauge is not functioning properly, it

Flowmeters are used in hydraulic power supplies

could lead to damage to the system it monitors. It could

and component test benches to indicate the rate of flow

also be a safety hazard to personnel. For this reason,

of fluids, usually in gallons per minute (fig. 8-39). One

NAVAIRSYSCOM requires that pressure gauges used

use of a flowmeter, for example, is in testing the output

to service tires, shock struts, and hydraulic

of pumps. The most common type of flowmeter used is

accumulators be calibrated every 30 days. On

the rotameter, which is described in Fluid Power,

servicing equipment with multiple-gauge

NAVEDTRA 14105.

installations, only the gauge or gauges that monitor the

8-32