should remember that all systems can be broken down

2

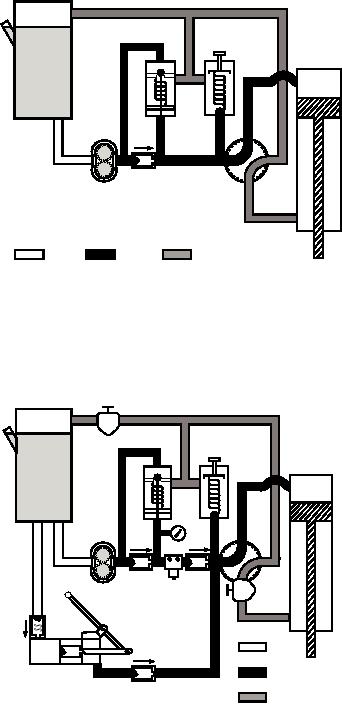

into a simplified system (as shown in figures 8-43

5

7

through 8-46). Thus, even the most complex system

1

can be analyzed, not from the standpoint of a complex

system but from that of a simple system.

TYPES OF HYDRAULIC SYSTEMS

ss

There are two types of hydraulic systems used in

6

4

3

support equipment, open-center and closed-center.

Open-Center System

RETURN

PRESSURE

SUCTION

An open-center system is one that has fluid flow

ASf08045

Actuating cylinder

5. Relief valve

1.

but no pressure in the system whenever the actuating

Reservoir

6. Check valve

2.

mechanisms are idle. Fluid circulates from the

Power pump

7. Pressure regulator

3.

reservoir, through the pump, through the directional

Selector valve

4.

valves, and back to the reservoir. Pressure developed in

Figure 8-45.--Hydraulic system with a relief valve and

regulator incorporated.

an open-center system is controlled by open-center

Directional valves and is limited by a system relief

valve. Figure 8-47 shows an open-center system. Note

2

14

the position of the directional valves and the fact that

5

the valves are connected in series. In this type of

7

1

system, there is no pressure in the system until one of

the subsystems is actuated by the positioning of the

8

directional valve. When in the neutral position (view

13

3

A), the open-center directional valve directs the fluid

ss

ss

to the return line. When the directional valve is

4

positioned out of neutral, pressure builds up in the

9

6

10

actuating section and operates the selected mechanism

(view B). When an open-center system is not being

12

SUCTION

used (no actuating mechanisms), the pump is said to be

ss

11

idling because there is no pressure buildup in the

PRESSURE

ss

system. Therefore, there is no load on the pump. Fixed

RETURN

ASf08046

displacement pumps are used in open-center systems

Actuating cylinder

8. Reservoir standpipe

1.

and normally do not require a pressure regulator.

Reservoir

9. Check valve

2.

Power pump

10. Pressure line filter

3.

Closed-Center System

Selector valve

11. Check valve

4.

Relief valve

12. Hand pump

5.

Check valve

13. Pressure gauge

6.

A closed-center system always has fluid stored

Pressure regulator

14. Return line filter

7.

under pressure whenever the pump is operating.

Figure 8-46.--Complete hydraulic system.

However, when pressure is built up to a predetermined

value, the load is automatically removed from the

mentioned, this system includes more check valves, a

pump by a pressure regulator or the integral control

pressure gauge, filters, and a hand pump. The hand

valve of the variable displacement pump. The

pump is added as an auxiliary system, normally used as

h y d r a u l i c s y s t e m s h ow n i n fi g u r e 8 - 4 6 i s a

an emergency power source in case of failure of the

closed-center system. In a closed-center system,

main power pump.

multiple Directional valves are arranged in parallel

The complete hydraulic system may be further

rather than in series, as in an open-center system.

expanded by including a pressure manifold, more

N OT E : S o m e s y s t e m s m a y e m p l o y b o t h

selector valves, actuating mechanisms, and more

power-driven pumps connected in parallel. But, you

open-center and closed-center features.

8-37